Sustainable and long-lasting thermal insulation with the strength and durability of concrete

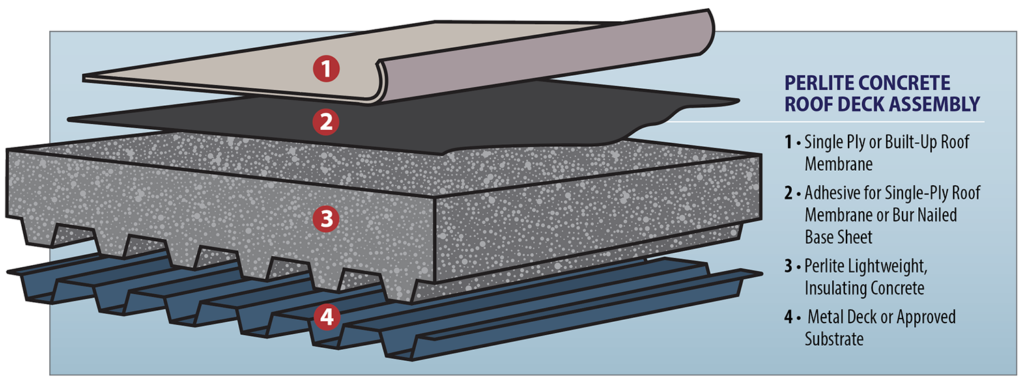

Perlite Lightweight Insulating Concrete is a mix of perlite lightweight construction aggregate (ASTM C 332, Type 1), cement (OPC, Type 1, ASTM C150), air entraining agent admixture (ASTM C260) and water. Perlite lightweight insulating concrete roof decks offer unique sustainable thermal insulation, ultra-lightweight, and fire-resistance while replacing plastic/ synthetic insulators (such as polystyrene, polyurethane and others) and a sloped-to-drain topping screed, all in a one-phase application. This versatile design reduces the roof buildup thickness and construction time and cost. Among their useful properties, perlite lightweight concrete roof decks offer consultants, contractors, and clients the following benefits:

Superior Thermal Insulation

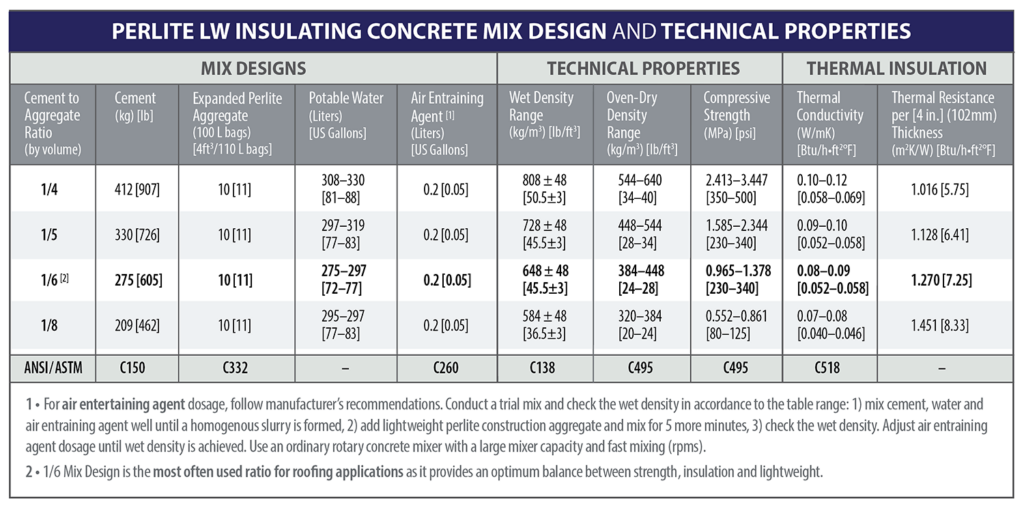

With a thermal conductivity of 0.07 W/mK – 0.12 W/mK (0.040 – 0.069 Btu/ h•ft°F). Perlite lightweight concrete roof deck is one of the world’s most advanced thermally insulating cementitious mixtures available offering 20x more protection from heat gain or loss than ordinary concrete. U-values of 0.30 W/m2K for standalone applications are commonly achieved, and are as low as 0.12 W/m2K when applied in combination with insulation board.

Different performance measures can be achieved by varying the density and/or thickness of the final application. Typical U-values for a 4 inch (101.6 mm) thick roof deck start at 0.12 Btu/h•ft2°F (0.6 W/m2K) and decreases with each additional measure of thickness. Table 1 provides a range of typical thermal resistance (R) insulating values per 4-inch thickness for various mix designs, useful in determining the desired thermal performance (R-value & U-value) and structural requirements for a given roof design. Note: The average thickness of the sloped-to-drain perlite lightweight concrete roof deck is considered to calculate the average U-value on the roof.

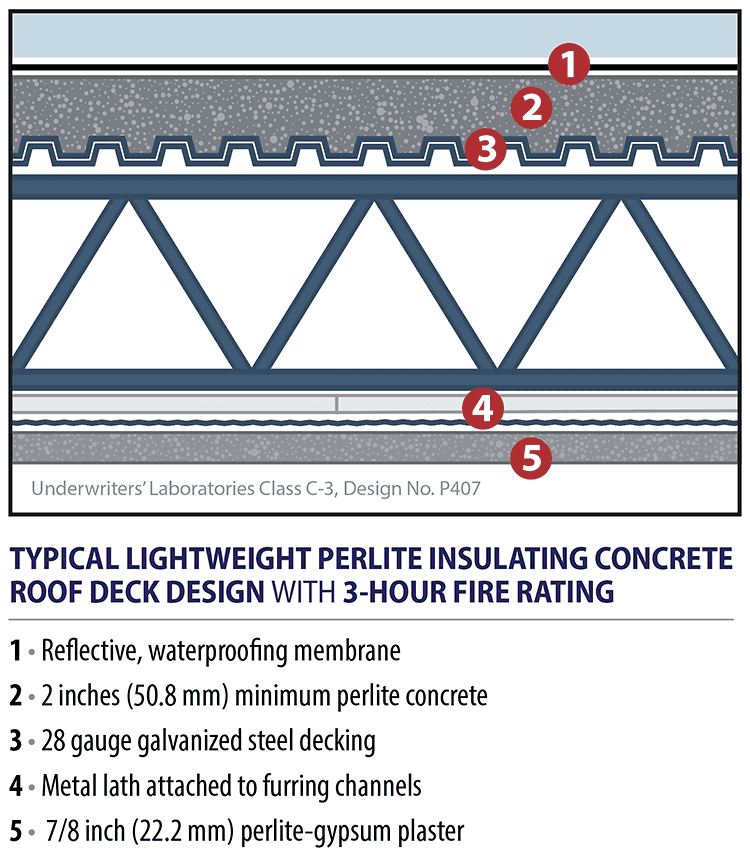

Excellent Fire Ratings

There are several perlite lightweight concrete roof deck designs available offering the benefit of between 1- and 3-hour fire ratings. A typical 3-hour rated roof deck design consists of a 2 inch (50.8 mm) minimum thickness of perlite lightweight insulating concrete applied over 28 gauge galvanized corrugated steel supported by steel joists 4 feet (1.22 m) on-center.

A ceiling constructed of 7/8 inch (22.2 mm) perlite gypsum plaster applied to expanded metal lath that is attached to 3/4 inch (19.1 mm) furring channels, and wire-tied to the lower chord of the joists completes the detail (see Figure 2).

Ultra-Lightweight

At Dry Density ranges between 20–40 lb/ft3 (340–640 Kg/m3), perlite lightweight concrete is among the lightest concrete mixtures available, helping to reduce dead loads on buildings and the overall strength needed to support a building in the event of an earthquake. The typical density of a perlite lightweight concrete roof design averages 27 lb/ft3 (432 kg/m3).

Slope-to-Drain

Perlite lightweight insulating concrete roof decks offer a smooth, monolithic, sloped-to-drain surface, ideal for receiving any kind of waterproofing solution (e.g., membrane, bituminous, PVC, cementitious, etc.). Perlite lightweight insulating concrete is highly workable and easy-to-screed and slope to internal drains or to the roof edge. Perlite concrete is delivered by transit mixer or it can be mixed on-site at the roof level. Once dispensed, it is simply screeded to the desired thickness and slope.

Bottom Photo: Strong, smooth, monolithic surface of a perlite lightweight concrete roof deck installation.

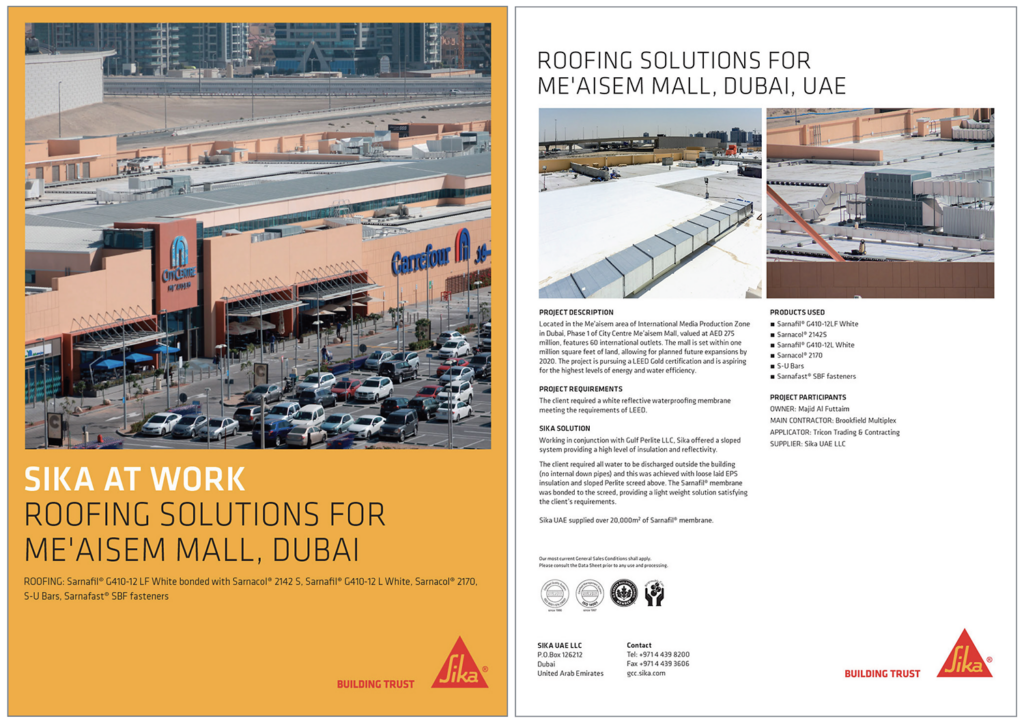

Sustainable Roofing

Perlite lightweight concrete is a sustainable thermal insulation that is long-lasting and durable. Thermal insulation performance is sustained throughout the design life of the building because of the inherent qualities of the materials with which it is composed. The thermal performance of synthetic insulators such as polyurethane (PU foam) and polystyrene foam degrades with time, losing their insulating value by up to 30% only 50 days after production. Perlite lightweight insulating concrete is LEED compliant, VOC-free, asbestos-free, and does not contain formaldehyde or other hazardous substances.

Perlite lightweight construction aggregate out-performs polystyrene and polyurethane (PU foam) on virtually all sustainability metrics such as: Global Warming Potential (GWP), Ozone Depletion Potential (ODP), Photochemical Oxidants Creation Potential (POCP), Eutrophication Potential (EP), Acidification Potential (AP), Embodied Energy (EE), and Embodied Carbon (EC).

Strong, Monolithic Roofing Base

Perlite lightweight concrete roof decks offer 3-5x higher compressive strength compared with foam concrete at the same density and 20-50x the strength of insulation board. Plus, it can withstand live loads of exposed waterproofing membranes.

Excellent Retrofit Roof Base

Perlite lightweight concrete provides an ideal material for re-roofing, restorations, and roof repairs. It does not add significant load to older structures while significantly improving the thermal insulation, and providing a sloped-to-drain hard surface to apply the new waterproofing layer to. Finally, this is achieved with a thin, one-phase application.

Be sure to check that the pre-existing insulation is intact, and that the support structure is capable of safely supporting the added layers of new roofing. All loose gravel and dirt should be swept off the existing roof prior to installation. For optimum roofing performance, it is recommended that drainage is provided by sloping the perlite lightweight insulating concrete.

To download a .pdf of the Perlite Lightweight Insulating Concrete Roofing brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright © 2023 Perlite Institute All Rights Reserved