A perlite insulating concrete pool base can substantially reduce heat loss to the ground

Perlite ore, when expanded, takes on a low-density cellular structure that makes it an extremely efficient insulation material. For a detailed explanation of perlite expansion, see PDF info sheet: Why Perlite Works.

Perlite insulating concrete pool base can substantially reduce heat loss to the ground thus keeping pool water warmer for a longer swimming season. This will reduce energy costs when pool water is heated. In addition, perlite pool base provides a firm, smooth, foundation that prolongs the life of vinyl liners.

Application

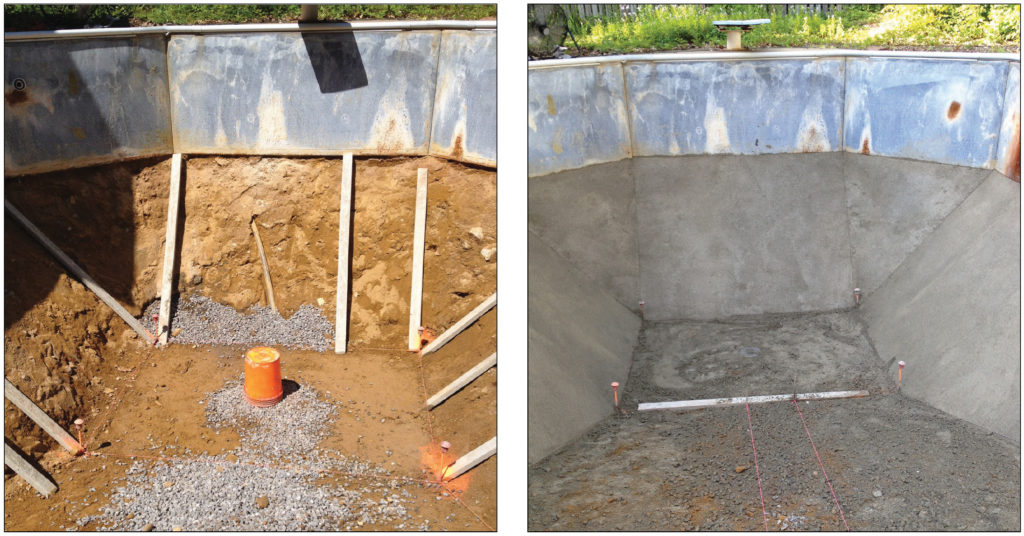

Perlite insulating concrete is placed following erection of pool walls. The concrete is site-mixed using paddle-type mixers, poured into the base area and screeded to the proper contour. It is recommended that the surface ahead of the pour be kept very moist and that the perlite concrete be fog sprayed every 15 minutes until the liner is installed.

It is further recommended that the foundation not be less than 2 inches (5 cm) thick. Above the coping sides, a 1 inch (2.5 cm) thickness is sufficient. The vinyl liner is installed and the pool filled immediately following concrete placement to eliminate dimpling problems and to smooth imperfections in the pool bottom. It is recommended that the pool not be used for 48 to 72 hours.

Mix Procedure

It is essential that the proper mixing procedure be followed to achieve best yield, workability and uniformity.

- Water, air-entrainment-agent and cement should be added to the mixer in that order. These components should be mixed one or two minutes until the slurry is uniform.

- Perlite aggregate should be added to the slurry, additional water added if necessary, and mixing should continue only long enough to create a uniform mix (one or two minutes). A proper mix will have a creamy consistency that will hold its shape without being runny. The inclusion of fibers will help eliminate dehydration cracking.

Over mixing can cause loss of yield, poor workability, and reduced strength. After the mix is uniform, and if there will be a delay in pouring the perlite insulating concrete, the mixer blades should be disengaged.

To download a .pdf of Perlite Insulating Concrete Pool Base for In-ground Vinyl Pools, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright © 2016 Perlite Institute All Rights Reserved