A series of effective filtration steps remove substances in crude fats and oils that impart undesirable flavor, color, and keep quality.

Fats and oils are essential nutrients in both animal and human diets. Both are called triglycerides, composed of one unit of glycerol and three units of fatty acids. Fatty acids are the building blocks for the hormones needed to regulate the body, so fats and oils are essential nutrients in both animal and human diets. At ambient temperature they can be solid, semi-solid or liquid. At room temperature, solids or semi-solids are called “fats” and in the liquid state are called “oils.”

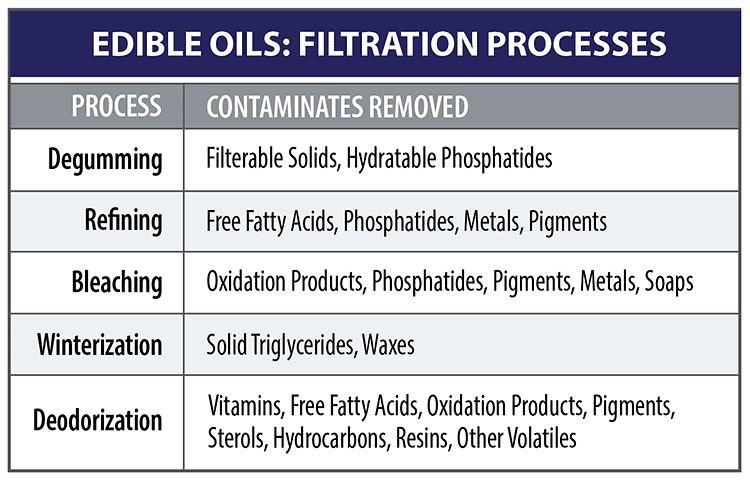

Food fats can be derived from vegetable or animal sources. Fats and oils obtained directly from rendering (animal source) or extraction of the oilseed (vegetable source) are called “crude” oils and fats. These crude fats and oils contain varying substances (free fatty acids, proteins, water and phosphatides) that impart undesirable flavor, color, and keeping qualities, which are removed through a series of processing steps (Table 1).

Filtration Process in Edible Oils

Filtration is a key process in the purification of edible, vegetable, and medicinal oil industry. Together with sedimentation and centrifugation, filtration is a primary step in the separation of oils and fats. Depending on the type of oil and final purpose, the oil is filtered in a sequence of process steps which can be divided as follows:

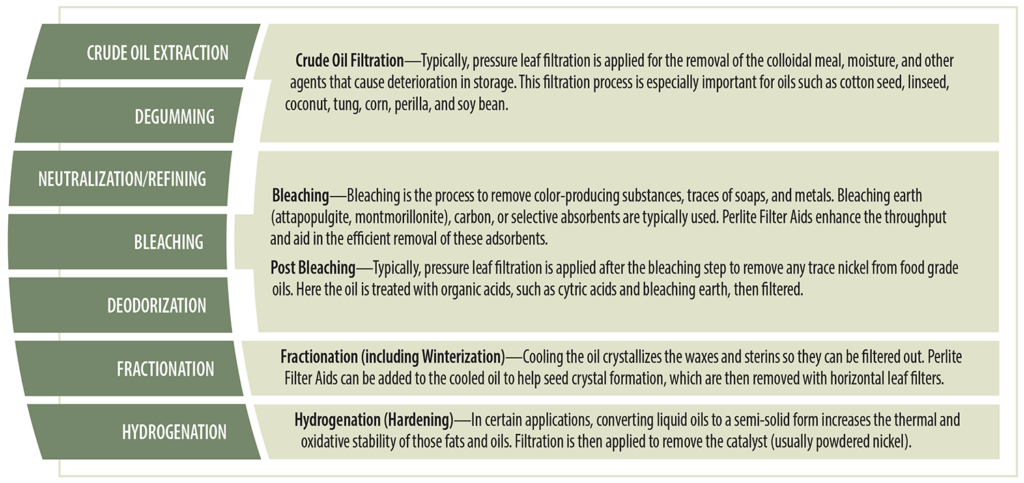

- Crude oil filtration: it is essential to remove remaining solids that are still present after the press. Commonly crude oil filtration is done in vertical pressure leaf filters.

- Miscella filtration: it aims for the removal of fines that have passed through the extractor. Miscella filtration provides a better-quality oil and hence a better quality lecithin.

- Bleached and/or detoxified oil filtration: this major step targets the removal of color, traces of soaps or detergents, gums, or metals while filtration is applied for the removal of the bleaching earths. Because this is a continuous process, two filters are used in the raw phase, one in operation, and another in the cleaning/stand-by mode.

- Winterized oil filtration: winterization removes crystallized components (waxes) commonly associated with some oils like sunflower, safflower, linseed, corn and cotton oil. Horizontal pressure leaf filters are used in this process. The pressure leaf filters are pre-coated with filter aid, while filter aid is also added during the process as a body feed to extend filter life.

- Catalyst filtration: the hydrogenation process is used to improve flavor stability and maintain oil quality. Nickel catalysts are used for hydrogenation of edible oils. The removal of the catalyst is done through the use of a pulse discharge filter or pressure leaf filter.

- Post bleaching filtration: This is a residual catalyst filtration to remove solid nickel catalyst after transitioning to nickel soaps. Vertical pressure leaf filters can be used to remove the bleaching earth.

- Deodorized oil filtration: This step is applied to remove impurities formed during deodorization.

- Safety filtration: safety filters are used after a cake filter to control the quality of the oil and ensure no particulate carry-over. Often bag filters are used in this filtration step.

- Polishing filtration: this is the final filtration step. Cartridge filters are used when there are high demands on the quality of the oil. These filters will provide more consistent and better effluent quality compared to a bag filter of the same micron rating.

Perlite Filter Aid Principles

A filter aid is an agent consisting of solid particles that improves filtering efficiency by building up a porous, permeable and rigid lattice structure—the filter cake—that retains solid particles and also helps flow control. The septum serves principally as a support for the filter cake. The filter aid forms a porous layer on the septum and becomes the filtering medium that traps the solids and septum from blinding. Irregularly shaped particles interlace and overlay leaving open spaces between the filter aid particles. The size of these openings is so minute that the unwanted solids are strained from the liquid, and the sheer number of openings compensates for their small size, resulting in fast flow rates and brilliant clarity.

Filter aids may be applied either as precoat on the septum and/or as body feed in the liquid. As precoat, filter aid can be applied as a thin layer over the filter before the suspension is pumped to the apparatus. A precoat prevents the suspension particles from becoming so entangled in the filter medium that its resistance becomes excessive. Further, it facilitates the removal of cake at the end of the filtration cycle.

Perlite filter aid is created through the expansion of perlite ore, the milling of that expanded perlite, and the classification of milled expanded perlite using cyclonic air separation. A range of perlite filter aid grades are produced, some finer, and some coarser, with varying technical properties to optimize the process filtration capacity for a wide variety of applications. The various grades utilize the jagged interlocking structures of the particles to create billions of microscopic channels between the filter aid particles.

Advantages of Perlite Filter Aids

- Local supply—near the use point

- Specially tailored to the local application

- Minimal lead time

- Low filter cake density (< 270 kg/m3)

- Wide permeability range of grades

- Less cake cracking and easy cake release

- Wide variety of properties (density, particle size)

- More economical filtration (same volume, half the mass)

- Perlite filter aids satisfy the US Food Codex and relevant EU regulations

- Not chemically modified material

- Sterile and inert nature

- Safe handling and easy disposal

Perlite Filter Aids vs. Diatomaceous Earth (DE) Filter Aids

Diatomaceous earth (DE), or simply diatomite, is made from the fossilized remains of tiny, aquatic organisms called diatoms. Their skeletons are made of a natural substance called silica. Over a long period of time, diatoms accumulate in the sediment of rivers, streams, lakes, and oceans. This material is mined and calcined (heated at high temperature) to destroy any organic matter and agglomerate the diatoms together. The diatomaceous earth is then milled and separated into various filter aid grades through the use of air flotation.2

Perlite filter aids are functionally like DE filter aids, and usually both are used when the collected solids are not wanted for subsequent treatment.3 However, the different origin and physicochemical properties render perlite advantageous in the following ways:

- A wide network of perlite suppliers is established assuring quick and uninterrupted local supply. This is not always the case for DE, which has long lead times and requires significant inventories to account for variations in demand.

- Perlite has 30-50% less bulk density thus comparable filter applications typically require 30%-50% less additive.4,5

- Perlite filter aids form lower density cakes than diatomite filter aids of comparable grades.6,7

- Perlite filter aids generally contain no, or very little crystalline silica, thus do not pose a health hazard.

- As a consequence of its inert nature, perlite filter cake is not subject to the strict regulations governing its disposal.8

- DE possess higher soluble iron that may affect the quality of edible and drinkable products.8

OTHER RELEVANT PUBLICATIONS FROM THE PERLITE INSTITUTE

Available for free at www.perlite.org/library

- Perlite Filter Aid (PFA) for Vacuum & Pressure Filtration

- Perlite Filter Aid: Beer Filtration

- Explained: Perlite Filter Aids

- Perlite Filter Aid: Extractive Metallurgy

BIBLIOGRAPHY

[1] Brooks D, Berbesi R, Hodgson A. AOCS Lipod Library-Optimization of Bleaching Process. https://lipidlibrary.aocs.org/edible-oil-processing/optimization-of-bleaching-process. Accessed February 28, 2023.[2] Bergquist G. Relationship, selection, and optimization of filter aid, filter media and clarification technologies for contaminant fines removal from process slurries and liquids. In: Industry Candidates Poster Session 2019, Held at the 2019 AIChE Spring Meeting and 15th Global Congress on Process Safety. ; 2019:110-125.

[3] Trevor Sparks GC. Section 2 – Filter Media. Filters Filtr Handb (Sixth Ed. 2016:55-115. doi:10.1016/B978-0-08-099396-6.00002-2

[4] Cheremisinoff NP. Industrial Filtration Equipment.; 1998. doi:10.1016/b978-075067047-0/50005-2

[5] Perlmutter BA. Types of Filtration Systems. Solid-Liquid Filtr. 2015:35-45. doi:10.1016/b978-0-12-803053-0.00003-1

[6] Sutherland K. Filters and Filtration Handbook. 5th ed. Butterworth-Heinemann; 2008

[7] Zafisah NS, Ang WL, Johnson DJ, Mohammad AW, Hilal N. Effect of different filter aids used in cake filtration process on the removal of suspended solids in anaerobically digested palm oil mill effluent (POME). Desalin Water Treat. 2018;110:362-370. doi:10.5004/dwt.2018.22349

[8] Jackson RS. Post-Fermentation Treatments and Related Topics.; 2014. doi:10.1016/b978-0-12-381468-5.00008-7

To download a .pdf of the Edible Oils Filtration brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright © 2023 Perlite Institute All Rights Reserved