The physical character of expanded perlite lends itself to a variety of special purposes—including use as a filler material in milled flake form, aggregate bubble form, and individual microspheres. For a detailed explanation of perlite expansion, see PDF information sheet: Why Perlite Works

ADVANTAGES OF PERLITE AS A FILLER

- Weight reduction

- Shrink and/or crack resistance

- Low volume-based cost compared to binders and some other fillers

- Whiteness

- Impact Resistance

- Machinability and ease of sanding

- Nail and screw holding ability

- Flexural strength modification

- Very fine texture in coatings

- Gloss and sheen control

- Pigment extension

- Inertness and non-toxicity

- Water and/or air permeability

- Fire resistance

- Insulation

- Modification of acoustic properties

- Available in various sizes and densities

Perlite Flake

Perlite glass flake consists of broken, expanded perlite particles to form glass flakes with an interlocking, 3-dimensional structure. This structure helps reduce shrinkage upon drying or curing, maintaining the physical dimensions of the host material.

Typical uses for perlite glass flake fillers are water-based construction compounds, paints, asphalt, concrete, plaster, and resin-based castings.

Flake size is, generally, below 300 microns (50 mesh) in size – averaging between 20 and 70 microns in diameter. Density ranges from 5 to 15 lbs. per cubic foot (80 – 240 kg/m3).

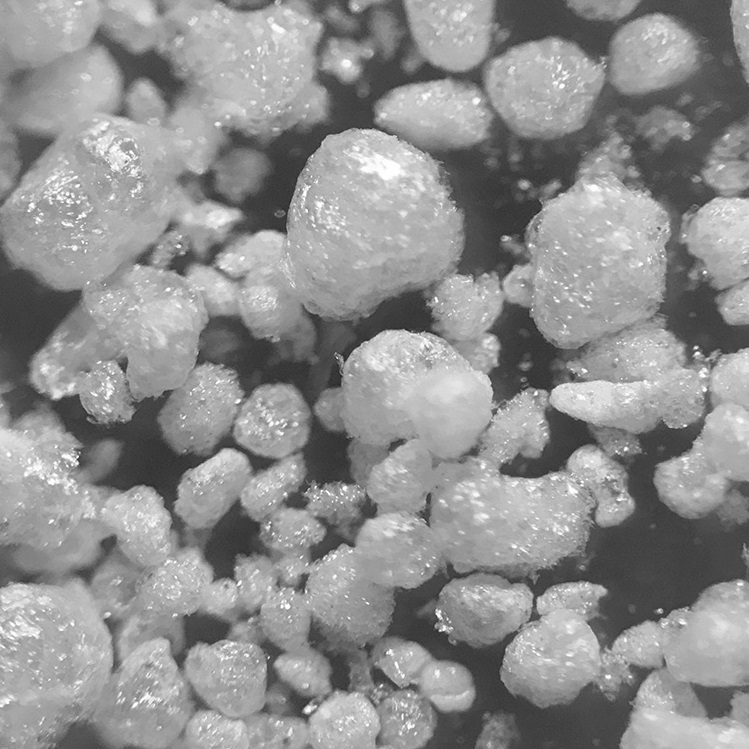

Perlite Bubbles

Perlite fillers made up of clusters of glass bubbles are used in a wide variety of applications – some of the most common being in the production of acoustic ceiling tiles, lightweight cement, and insulating plasters. Particle sizes range from 1,000 microns (16 or 18 mesh) down to below 200 microns (80 mesh). Densities can range from 4 lbs. per cubic foot up to about 19 lbs. per cubic foot (64 – 300 kg/m3). Other applications include use as a constituent in fire-rated door cores, where lightweight, inert and inorganic qualities enhance fire resistance and material workability. The shape of lightweight perlite fillers promotes good bonding with the host material.

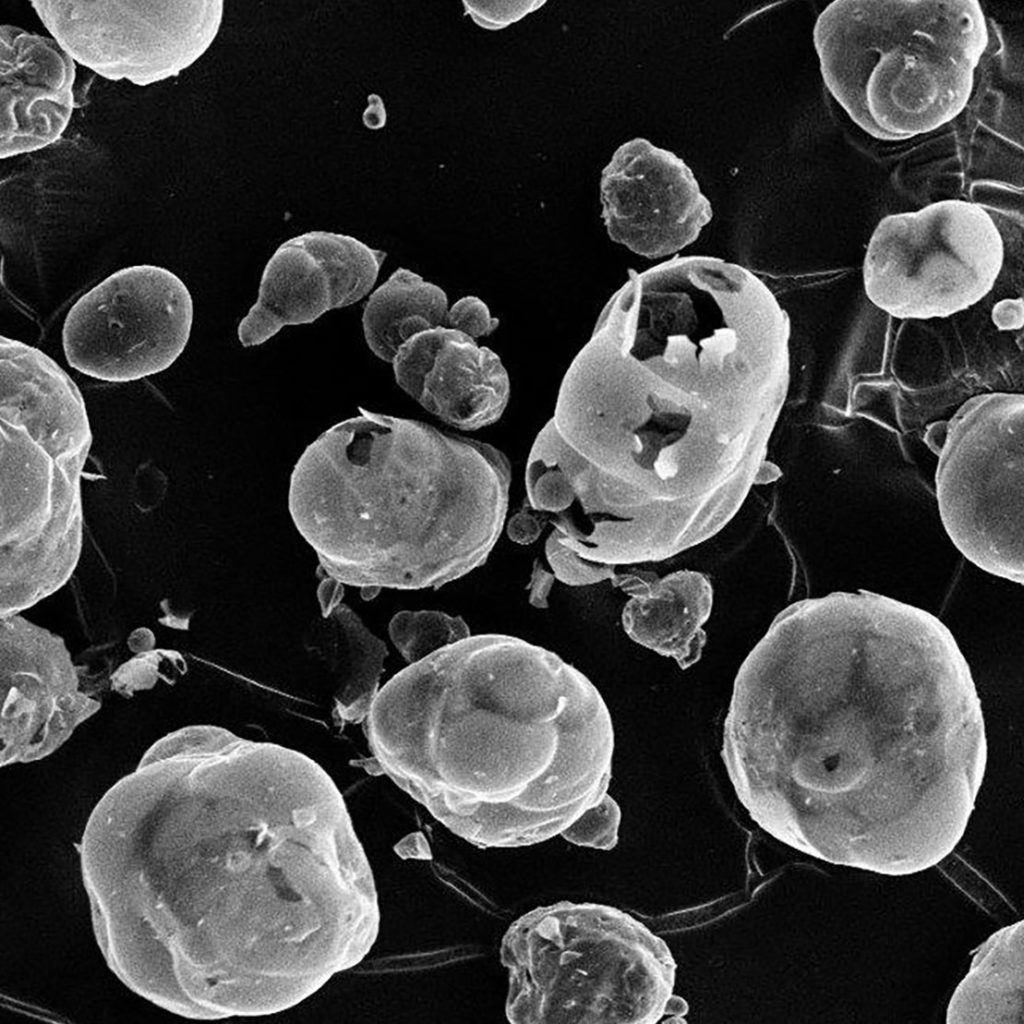

Perlite Microspheres

Perlite microspheres are a special subset of perlite fillers and require advanced manufacturing and classification techniques to produce. They consist of discreet hollow spheres of expanded perlite – generally between 10 and 300 microns in size. Densities vary from 6 lbs. per cubic foot to as high as 28 lbs. per cubic foot (96 – 450 kg/m3). Perlite microspheres are sometimes coated to enhance hydrophobic qualities or bonding properties needed for certain applications. Specialized technology now allows the production of individual, unbroken perlite bubbles and further classification can lead to even more uniform qualities for special uses. The spherical nature of these microspheres enhances flowability.

Fire-rated door cores made using perlite as a lightweight functional filler.

Perlite serves as a lightweight filler in cast stone products.

Auto body repair putty enhanced with perlite.

An exterior siding panel using perlite as the filler.

To download a .pdf of the Perlite as Filler brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright© 2017 Perlite Institute All Rights Reserved