Perlite Concrete Offers Many Advantages Beyond Its Light Weight.

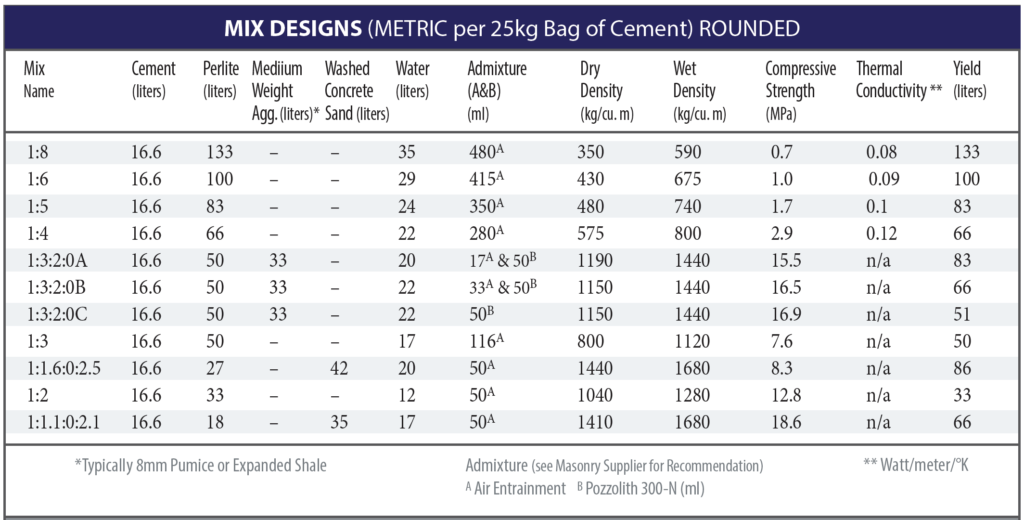

This product guide contains various mix designs for lightweight concrete, utilizing perlite as the primary aggregate, which may be used as stated or as a starting point for your own custom mixes.

Perlite lightweight concrete is used in many different applications. These include lightweight tile mortar, statuary, decorative stone, gas-fireplace logs and floor fills.

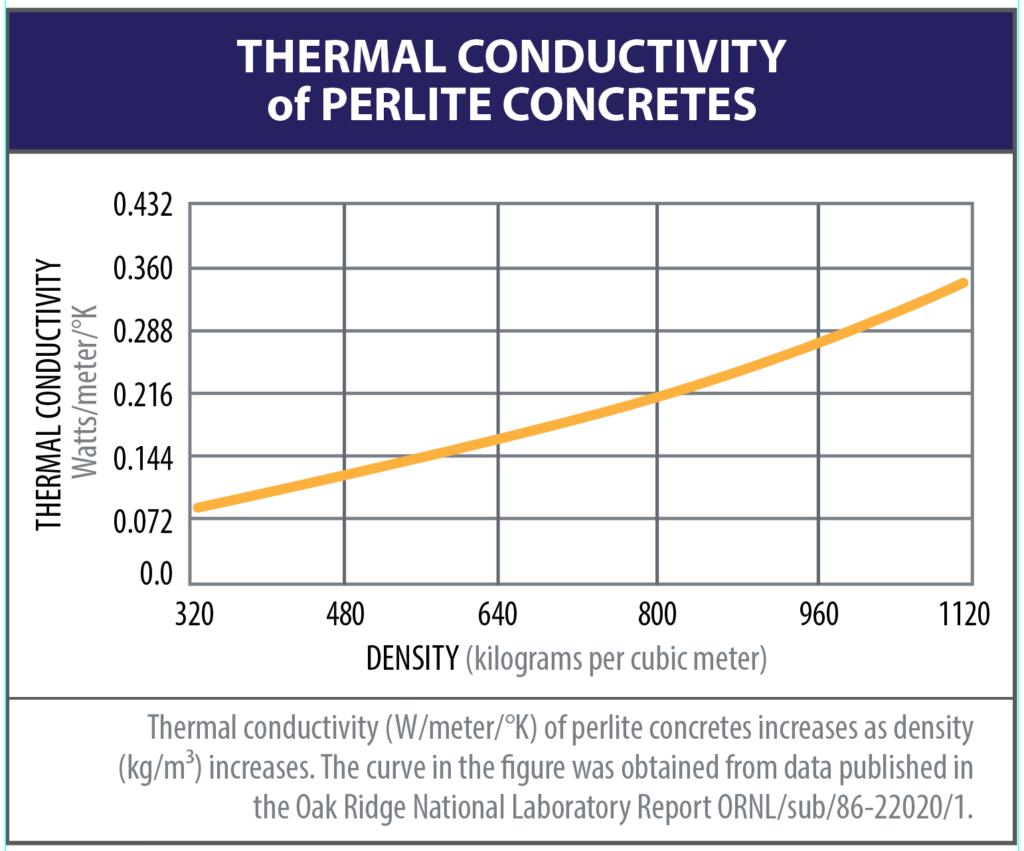

Perlite concrete, while not usually suited for structural or load bearing uses, offers many advantages beyond its light weight. Perlite concrete provides better noise reduction and thermal insulating properties than conventional concrete. Generally speaking, the lighter the weight, the greater the insulative properties.

Other Perlite Concrete Applications

- Chimney Lining

- Pool Bases

- Sound/Firewalls

- Tank Insulation

General Considerations

- The addition of sand to a perlite/cement mix will increase the density and compressive strength.

- The addition of medium-weight aggregate (pumice or expanded shale) will increase the density and compressive strength.

- The addition of fibers increases the tensile and flexural strength of perlite concrete,thereby reducing shrink cracking.

- The addition of air entraining agents reduce the density and compressive strength of the mix, and improves freeze/thaw performance.

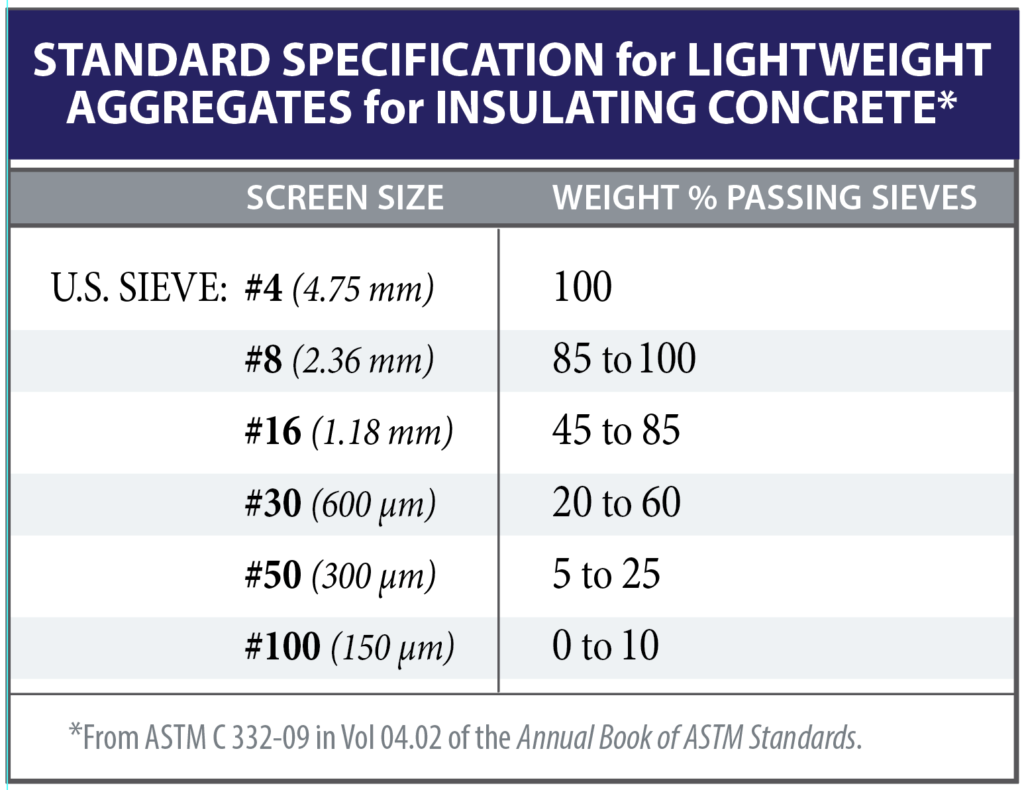

- A range of aggregate size is desirable for increasing compressive strength. Super-plasticizers and water reducers can also be used to increase strength.

- Finer aggregate particles can be used to produce smoother finishes.

Mix Instructions

Proper mixing will assure the maximum yield and uniformity. Low shear, low RPM mixers (similar to plaster mixers) are recommended for best results.

- Add all materials except perlite to mixer; then mix until this slurry is fairly uniform. Two minutes will usually suffice.

- Add all perlite; then mix again only long enough for a uniform mix, probably another two to three minutes. Excess water and/or under mixing may reduce yield and workability. Over mixing may degrade the perlite and increase concrete density, reducing yield. Optimum mixing cycle usually determined with one or two trial batches.

To download a .pdf of the Overview of Perlite Concrete brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright© 2015 Perlite Institute All Rights Reserved