Expanded perlite is lightweight, fire resistant, thermally insulating, and sustainable—a top eco-friendly choice for 3D-printed construction.

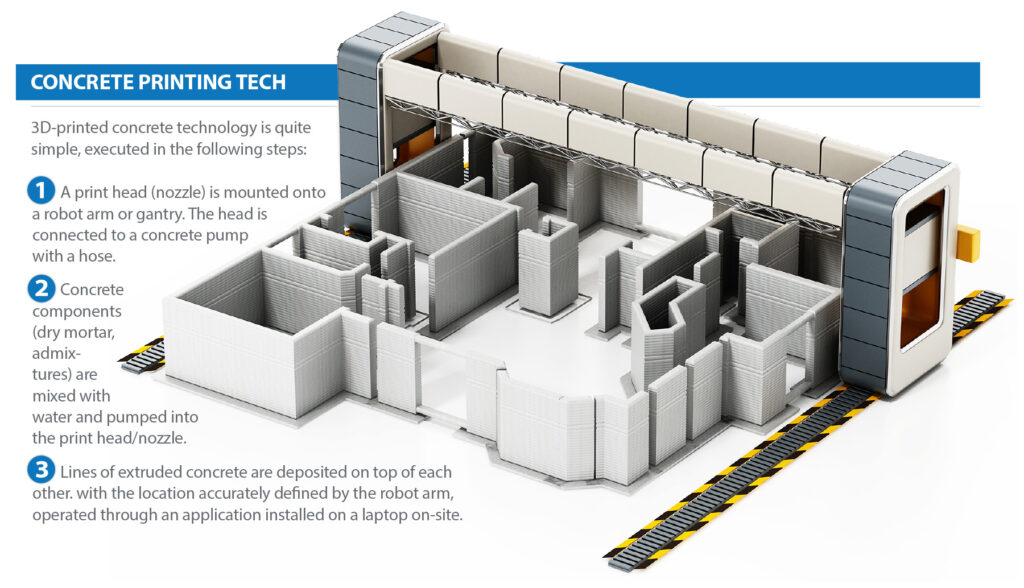

3D-printed concrete construction is revolutionizing the building industry by offering faster, labor-free, energy-efficient, sustainable, and advanced architectural design alternatives to traditional methods.

This innovative approach is gaining traction in regions with urgent housing demands, material and construction labor shortages, and advanced projects seeking architectural design freedom, building innovation, and sustainability. 3D-printed concrete is utilized worldwide, at various construction projects, such as residential and commercial buildings, architectural landmarks, infrastructure projects, and emergency shelters. Additionally, it plays a key role in developing affordable housing and custom architectural designs.

Some notable advantages of 3D-printed concrete buildings include:

- Rapid Assembly—Significantly shorter construction timelines in comparison to traditional constructions.

- Economic Viability—Reduced overall costs due to near zero-labor cost and less material waste.

- Environmental Responsibility—Sustainable designs with minimal excess materials.

- Architectural Versatility—Ability to craft unique, intricate, and curved structures with ease.

- Emergency Housing Solutions—Quick deployment of shelters in crisis situations.

Perlite in 3D-Printed Construction: A Dual-Purpose Material

Perlite is a versatile, sustainable, thermal insulating, fire-resistant, and lightweight material often used in 3D-printed constructions, offering both structural benefits and insulation properties. In addition, it exhibits outstanding sustainability characteristics, making it one of the most environmentally responsible choices among insulation materials1. It can be incorporated in two main forms:

- As a Filler in Concrete Mix—In that case, expanded perlite is used as a filler or “lightweight aggregate” in the 3D-printed concrete mixture, providing various benefits, including improved workability and flow, as well as weight reduction to the whole structure.

- As Loose-Fill to Insulate Building Wall Cavities—3D-printed concrete walls consist of two sides of 3D-printed concrete at a thickness of appx 2 inches and a wide cavity in between, with a width varying between 4 and 12 inches. Expanded perlite is used to loose-fill the external 3D-printed wall cavities, providing superior thermal insulation (U-value as low as U = 0.12 W/m2K, Passive House classification), ultra-lightweight construction, excellent fire resistance of 240 minutes, and acoustic insulation.

It is the most sustainable, non-combustible (Class A1/DIN 4102), easy-to-install, and cost-effective insulation for the 3D-printed external walls. Find more information in the guide for the use of Perlite as Loose-Fill Insulation2.

1 • www.perlite.org/wp-content/uploads/2024/01/Perlite-Sustainable-Insulation.pdf

2 • www.perlite.org/wp-content/uploads/2018/03/perlite-loosefill-insulation.pdf

Perlite in 3D-Printing: Insights from Recent Research

Expanded perlite is currently being explored and utilized in 3D-printed concrete constructions. Some recent research studies have shown the beneficial impact of the incorporation of expanded perlite in the properties of the final composite as well as the 3D-printing procedure, which is thus worth noting:

Jiang et al. studied the replacement of study with expanded perlite in 3D-printed foam concrete[1]. They found that by using perlite, the stability of the foam improved, enhancing the workability of the mixture and increasing the constructability of printed concrete. Furthermore, analyses of mechanical properties, porosity, and pore size distribution showed that at the same dry density, foam concrete with a higher expanded perlite replacement ratio exhibited higher compressive strength, with a maximum strength increase of up to 39%. Moreover, the introduction of expanded perlite optimized the pore distribution of the foam concrete, resulting in a more uniform material structure.

In another study, Pasupathy et al. investigated the influence of lightweight porous aggregate on the rheological properties, printability, and hardened properties of foam concrete for 3D-printing applications[2]. The introduction of expanded perlite as a replacement for fine aggregates (i.e., sand) in 3D-printable foam concrete substantially reduced the foam content to reach the same density, while enhancing the fresh and hardened properties of 3D-printed foam concrete. More specifically, they found that:

- The extrusion method used in the work does not affect the foam stability in 3D-printed foam concrete.

- The rheological parameters, such as static yield stress, dynamic yield stress, and plastic viscosity of the perlite-based foam concrete, are considerably higher than those in sand-based foam concrete mixes at similar densities.

- Compared to the sand group specimens, the compressive strength of the EP group 3D-printed concrete was high in all three of the tested directions.

- The interlayer bond strength of sand-based foam concrete is lower than the EP group at similar density ranges. This is because of the reduction of the effective contact area between the filaments due to the presence of more air voids.

- Porosity analysis and the SEM image analysis indicate that the porosity and the pore size are reduced with the incorporation of perlite.

Azami et al. also studied the replacement of natural sand by expanded perlite in concrete 3D-printing, with a similar focus on the post-fire properties of printed samples[3]. Among the different replacement ratios, the 25% was found the most beneficial (25, 50, 75 and 100%), since comparison of the perlite specimens with control specimens shows that the interlayer bond strength at room temperature increased and the compressive and flexural strengths declined while the specific weight declined by 9%, leading to a more lightweight concrete. Additionally, following exposure to 800°C, the perlite specimens exhibited better fire resistance compared to the control specimen. The sample with 25% replacement of sand with expanded perlite showed enhanced percentages of residual compressive bond and flexural strengths, compared to the control specimens.

In another study, Mohammad et al. studied the development of high-strength, lightweight concrete mixture suitable for 3D printing in construction, by replacing the normal aggregates either partially or entirely by expanded perlite, aiming for better thermal insulation that would result in decreasing energy usage within the life cycle of the structure[4]. The replacement ratio of natural aggregates by expanded perlite was 20 to 100 vol.% with an increment of 20 vol.%. materials testing includes measurement of compressive strength, flexural strength and thermal conductivity. With 100% replacement, a reduction of thermal conductivity by 62% (0.69 W/mK) was achieved, while 28-day compressive strength was found at 42 MPa. According to the authors, the specific mix design is appealing for 3D printing in constructions2 as it reduces the environmental impact of the construction by improving the thermal insulation and thus decreasing the energy consumption during the building operation.

These findings suggest that expanded perlite is a viable additive in 3D-printed concrete since it enhances foam stability (in foamed concrete), workability and constructability, and under proper formulation, it can improve mechanical properties and interlayer bond strength. Additionally, it optimizes pore distribution, reduces density, enhances fire resistance, and significantly improves thermal insulation because of the reduced thermal conductivity, contributing to more lightweight, durable, and energy-efficient concrete structures.

Perlite Lightweight Insulating Concrete Infill in 3D-Printed Concrete Walls

A key advancement in this domain is the incorporation of perlite lightweight insulating concrete to infill the cavities between 3D-printed concrete walls (Figure 4). Perlite lightweight insulating concrete adds unique technical properties to the 3D-printed concrete wall, as it delivers superior thermal insulation, 240-minute fire-resistance, acoustic insulation, while maintaining structural reliability, bonding the two thin 2-inch 3D-printed sides of the wall together in a solid concrete wall, eliminating the surface cracking of the 3D-printed concrete.

(Photo Courtesy of Gulf Perlite LLC)

Perlite lightweight insulating concrete never rots off or deteriorates, and it is not affected by weeds or bacteria. The technical properties of the 3D-printed concrete wall infilled with perlite lightweight insulating concrete lasts for a lifetime. By leveraging perlite lightweight insulating concrete within 3D-printed concrete walls, the construction sector is moving towards innovative, more sustainable, resilient, and efficient building practices, ideal for urban expansion and remote developments alike.

The usual 3D-printed walls with perlite lightweight insulating concrete are one-story and two-story residential buildings, guard rooms, and exhibition prestige buildings.

INFILL SPECIFICATIONS

Perlite lightweight concrete is mixed in situ and placed in 3D wall cavities. Perlite lightweight concrete infill offers:

- Fire-resistance, min. 240 minutes @ thickness of only 4 inches

- Ultra-lightweight, perlite lightweight insulating concrete dry density is only max. 440 Kg/m3

- Low thermal conductivity: 0.08 W/mK

- Acoustic insulation: STC = 61 dB @ thickness of 12 inches

- Thermal insulation: U = 0.20 W/m2K @ thickness of 12 inches

- Compressive Strength: 1.0 – 1.4 MPa

OTHER IMPORTANT FACTS:

- Sustainable building material: Thermal insulation with concrete performance and durability that lasts for a lifetime

- Plaster-free constructions: Clean site, no wastage

- Significantly less manhours

- Architectural flexibility: Any shape, including curved walls and rounded corners

REFERENCES

[1] Jiang, S.; Wang, Y.; Hua, S.; Yue, H.; Zhang, Y. Preparation and Performance Characterization of Low-Density 3D-Printed Expanded Perlite–Foam Concrete. Appl. Sci. 2024, 14, 6796, doi:10.3390/app14156796 [2] Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Enhancing the Properties of Foam Concrete 3D Printing Using Porous Aggregates. Cem. Concr. Compos. 2022, 133, 104687, doi:10.1016/j.cemconcomp.2022.104687 [3] Azami, Z.; Mousavi, M.; Bengar, H.A.; Javadi, A. Post-Fire Properties of Lightweight 3D Printed Concrete Containing Expanded Perlite. Mag. Concr. Res. 2024, 1–12. [4] Mohammad, M.; Masad, E.; Seers, T.; Al-Ghamdi, S.G. High-Performance Light-Weight Concrete for 3D Printing. In Second RILEM International Conference on Concrete and Digital Fabrication; 2020; pp. 459–467.To download a .pdf of the 3D-Printed Concrete Buildings brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright © 2025 Perlite Institute All Rights Reserved