Bedding materials in poultry farming contribute to the comfort, health, and hygiene of animals.

Choosing the right material is crucial for the overall health, well-being, and productivity of the birds. Bedding material serves a number of important purposes on chicken farms:[1–3]

Prevents health problems: The bedding material helps prevent footpad dermatitis, a common issue in poultry. It provides a comfortable surface that reduces the likelihood of skin irritation and lesions on the birds’ feet.

Moisture absorbent: Bedding material absorbs moisture and helps keep the living environment dry. This is important to prevent the growth of harmful microorganisms, reduce the risk of disease, and maintain good hygienic conditions for animals. It reduces flies and odors as well.

Manure management: Bedding material plays an important role in manure management, which is essential to maintaining a clean and healthy farm environment. It helps absorb excess moisture from manure, making it easier to handle and manage.

Dust control: Bedding materials can help control dust in barn areas, thereby improving air quality and respiratory health of poultry.

Nesting substrate: On bird farms, nesting materials provides poultry with a comfortable and safe place to lay eggs, contributing to the overall health and productivity of the flock.

Thermal insulation: Bedding material acts as a heat insulator, helping to regulate the temperature in the animals’ living space. Good insulation helps protect animals from extreme temperatures, keeping them warm in cold weather and cool in hot weather. This is important for maintaining optimal conditions, especially in areas with harsh weather conditions.

Comfort and welfare: Bedding material provides a comfortable and soft substrate for animals resting. This is especially important for animal welfare, as it helps prevent injury and provides an environment more conducive to rest and relaxation.

The ideal animal bedding material should possess several key properties:

- Cost-effective

- High absorbance

- Resistant to mold and fungi growth

- Easy to clean

- Easy and safe disposal

- Low in dust or dust free

- Thermal insulation

- Soft and comfortable

- Readily available

Expanded perlite meets the specifications that are set by the industry for substrate materials used in bird shreds. Its outstanding absorption capacity and low density possesses great performance for this purpose.

Case Study

Statement of the problem: The combination of high temperatures and humidity with absent or flawed ventilation in bird farms contributes to wet guano, which does not dry at the desired rate and does not accumulate on the coop floor into a kind of “pyramid” as to facilitate its management. The Israeli company, Agrekal, ran a project to investigate the efficiency of perlite to treat extreme dampness of the manure (guano) and mitigate the nuisance of flies and odors in coops.

Moreover, these conditions are ideal for the increased development and activity of flying insects, the most prominent and bothersome of which is the housefly, Musca domestica—which develop in large numbers in bird guano and is considered an environmental hazard and nuisance to birds and humans, especially to coop workers and residents in the environs. Furthermore, the odor nuisance of wet guano is severe.

Large numbers of flies can also cause great anxiety in the flock and affect its performance. Furthermore, flies are carriers of various diseases, such as the bacteria that causes contagious rhinitis, transfer the eggs of intestinal worms, and can even be hosts for several species of worms.

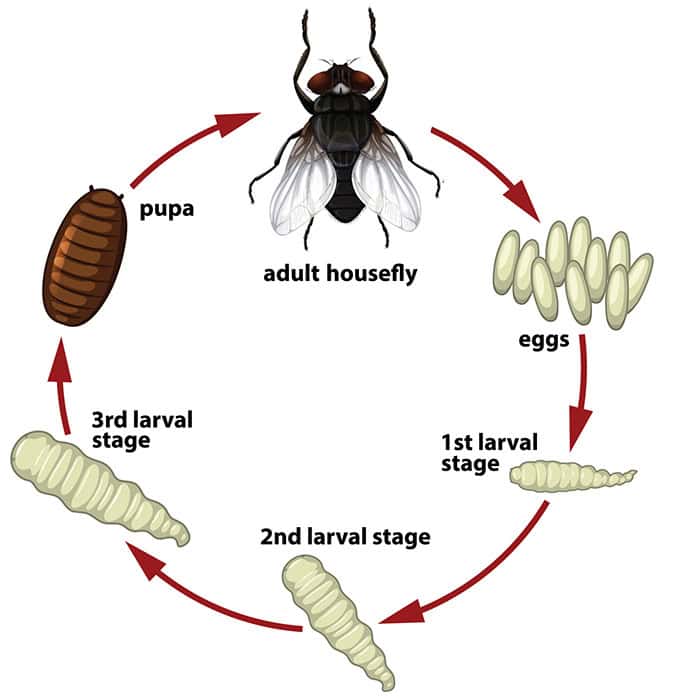

The fly’s development from egg, to larvae, pupa, and full grow fly depends on a suitable nutrient-rich organic material substrate and right temperature. These two conditions exist ideally in coops in Israel. The wet muck, which contains only 15–35% dry material, is an ideal substrate of organic material in large quantity, enabling larvae to grow easily. The housefly eggs are laid in muck, and the pupae are wrapped in a fairly hard shell that protects them from drying out and against the penetration of toxins. Drier muck prevents the development of the larvae; thus, it is preferable to keep muck as dry as possible. The second condition for the fly’s development is a comfortable temperature, which exists in Israel from April through November. In these conditions, the fly completes its life cycle in just 10–14 days, hence the rapid multiplication of flies in spring, summer, and autumn. Interestingly, according to some estimates, the number of adult flies at any given moment is only 30% of the total population; the rest are eggs, pupae, and larvae.

The larvae grow into pupae and shed their skin several times. After 5–7 days, the larvae are encased in a cocoon, and three days later, the fly hatches and is ready to mate and lay eggs. Therefore, any treatment directed only against adult flies without treating the young stages in the muck only treats the symptoms of the problem, not its root. Only an integrated treatment that includes pesticides during the growth stages will be effective over time. The resulting difficulty that arises is that these treatments must be carried out several times during the growth stages and in a synchronized way with other growers in the area, which is usually not the case. Fly and larvae extermination is relatively expensive, and many farmers avoid it for this reason.

Treatment of the Problem and Objective of the Study

The treatment can be applied in two levels: prevention and pest control. The right interface to eliminate larvae development, includes drying all the wet and damp areas. Wet muck in areas that are not properly ventilated and areas where water drips from broken drinking cups are primary places where flies lay eggs. So, it is important to eliminate this by improved ventilation, quick repair of any water issue, and the dispersal of quicklime in the damp area. Pest control should be avoided, if possible, because of the cost.

The objective of the study was the use of expanded perlite to dry the wet guano, especially in the summer, to build pyramids, and to evaluate the effect of pest control.

(Photos courtesy of Agrekal)

Application

Expanded perlite was used as an absorbent in egg laying bird coops that had muck on the floor. The perlite used had an LBD of about 70 kg/m3, and perlite was spread on wet guano in two different dosages: treatment A-15 L per m2 and treatment B-30 L per m2.

Findings and Conclusions

The implementation of the projects showed that:

- A reduction of death rate of poultry by 7% was achieved by the application of perlite. The reason behind this is:

– As soft material, perlite does not injure the throats of poultry.

– The reduction of moisture content by the use of perlite cumbers the development of fungi, and microbes and bacteria growth and spread. - Pesticide use against flies during the perlite treatment was found to be highly effective.

- Rapid drying of the muck also solved the problem of larvae and reduced fly infestation.

- Even after one sole treatment for guano drying contributes to building stable guano “pyramids.” Additional treatment will definitely improve the condition of the guano.

It is important to start activity at the right time, i.e. in late spring, immediately upon the appearance of moisture (puddles and larvae). It is also important to take preventative action.

Application Recommendations

- Perlite can be blended with other bedding materials.

- As far as the perlite size is concerned, fine fractions are expected to have better performance because of the higher specific surface area over coarser ones., and the higher water absorption.

- Perlite wetting is suggested to eliminate dust production during its application.

- While perlite is inert, its dust will make one cough so one may want to use a dust mask while handling it.

BIBLIOGRAPHY

[1] Guerrero-Legarreta I, Hui YH, editors. Handbook of Poultry Science and Technology Vol 1. Primary Processing. New Jersay: John Wiley & Sons, Inc.[2] Diarra S, Lameta S, Amosa F, Anand S. Alternative Bedding Materials for Poultry: Availability, Efficacy, and Major Constraints. Front Vet Sci. 2021;8:1–8.

[3] Guide to Good Farming Practices for Animal Production Food Safety.

To download a .pdf of the Expanded Perlite for Bedding Material in Poultry Farms brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright © 2024 Perlite Institute All Rights Reserved