Perlite is used in VIP cores as a cost-effective thermal insulation material

Many thermal insulation materials available on the market can be used to reduce heat loss. Vacuum Insulation Panels (VIPs) are high-performance thermal insulation products of exceptionally low thermal conductivity. They are composite materials with a core, wrapped in an air- and vapor-tight barrier envelope. Depending on the core material characteristics, the envelope is evacuated to an air pressure below 5 mbar and (heat) seal [1]. VIPs are well known for their exceptional insulating qualities; indeed, they offer thermal resistance that is up to ten times greater than traditional insulation materials. They are used to improve energy efficiency and minimize space needs in a variety of industries, such as packing, refrigeration, and construction. The creation of VIP technology is a major step toward the adoption of more environmentally and energy-conscious building techniques.

Basic Physics of Convectional Thermal Insulating Materials

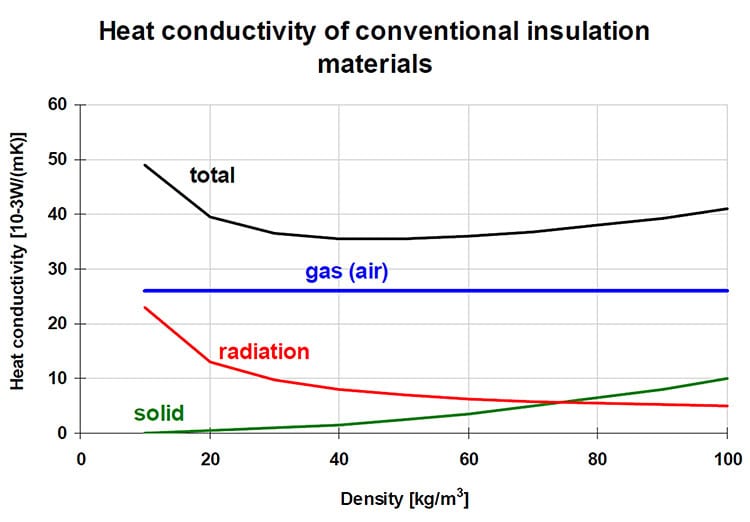

The thermal conductivity of a VIP is composed of four components: solid conductivity (ks), radiative conductivity (kr), gaseous conductivity (kg) and coupling conductivity (kcp). At sealing pressures lower than 0.1 mbar, where there is negligible gas inside the pores of the core material, the gaseous and coupling conductivity becomes negligible [2]. In conventional insulation materials like mineral wool, glass wool or organic foams, the total heat transfer is dominated by the contribution of the non-convective gas within the hollow spaces or pores (Figure 1).

The achievement of superior insulation properties, like VIPs, utilize vacuum technology, scoping the following:

- Elimination of conduction mean of heat transfer: Since there are no gas molecules to conduct heat, this means that heat transfer minimizes under the vacuum conditions.

- Reduction of convection: Convection requires a medium to transfer heat between different phases, and, by creating this vacuum, the elimination of air inside the panel causes drastic elimination of this mode of heat transfer.

Due to the state of the vacuum, the ideal thermal conductivity of a VIP is as low as approximately 0.004 W·m-1 · K-1, which is a factor that is five to ten times less than that of conventional thermal insulators[4]. Subsequently, vacuum insulation panels combine high thermal performance with limited construction thickness. Applying a vacuum in insulation panels significantly enhances their ability to prevent heat transfer, making them a highly effective solution for thermal management in various applications including buildings, refrigeration, and transportation.

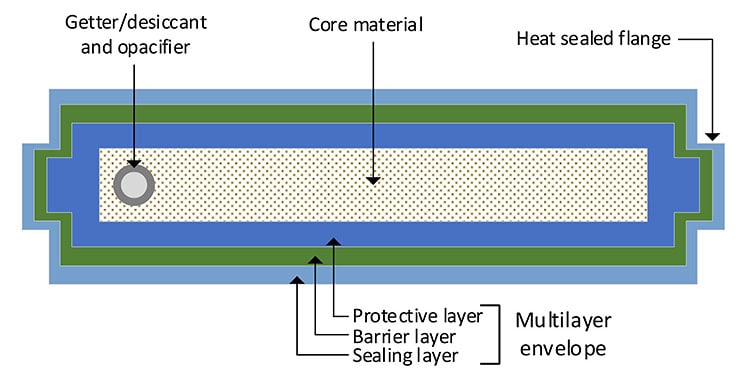

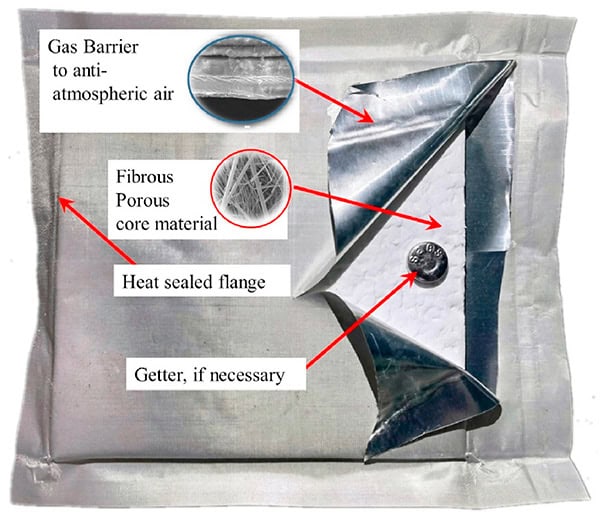

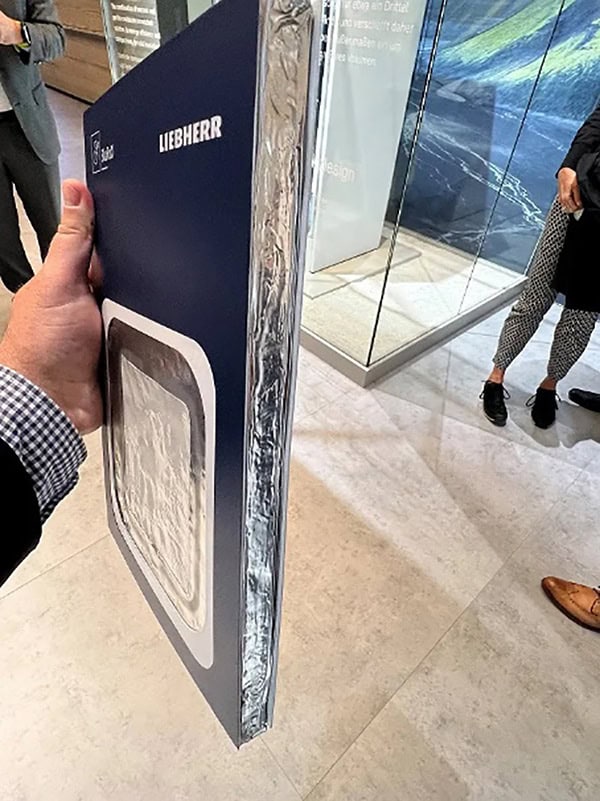

Figures 2, 3 • Schematic representations of a VIP cross section (figure 2)[5] and an actual VIP panel (figure 3).[6]

Anatomy of a VIP

VIP is a multilayer material consisting of the following:

- VIP Core: The main insulating material that controls the thermal performance of the product.

- Envelope: Surrounding the core and maintaining the vacuum inside the panel, the envelope preserves the desirable shape whilst simultaneously preventing air and moisture ingress.

- Getter material: These materials are placed to maintain the vacuum by absorbing any gases that may escape from the core or permeate through the barrier over time.

- Opacifiers: Added to scatter and absorb infrared radiation, these materials reduce this mode of heat transfer

- Sealing: Sealing materials close the barrier around the core material, ensuring it remains airtight.

- Valve: Some VIPs include a valve to allow re-evacuation of the panel if the vacuum degrades.

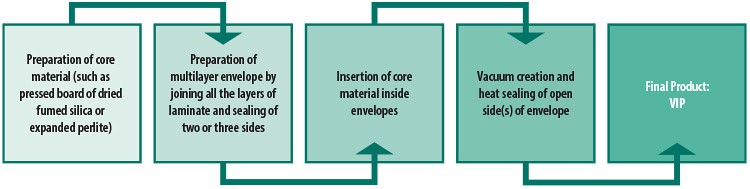

Usually, the VIP production route followed is the one described in Figure 4.

VIPs Per Application

Each type of VIP is designed to meet specific thermal performance, durability, and application needs, making them versatile solutions for a wide range of insulation challenges. Required product properties depend on the intended application. The main kinds of VIP, categorized by its intended application, are listed below:

- Building insulation VIPs: Designed to ensure long-term thermal performance and structural stability, applications of building insulation VIPs include walls, roofs, floors, and other parts of buildings where space-saving and high insulation are needed.

- Refrigerator and Freezer VIPs: These VIPs are used to provide high thermal resistance to maintain low temperatures efficiently. Typical uses include refrigerators, freezers, and cold storage units.

- Transport VIPs: Lightweight and able to withstand the demands of transportation, typical uses of transport VIPs include insulated shipping containers, refrigerated trucks, or cargo holds.

- Specialty VIPs: These products are tailored to reach the specifications of the individual application in aerospace, military, chemical industry, and medical devices.

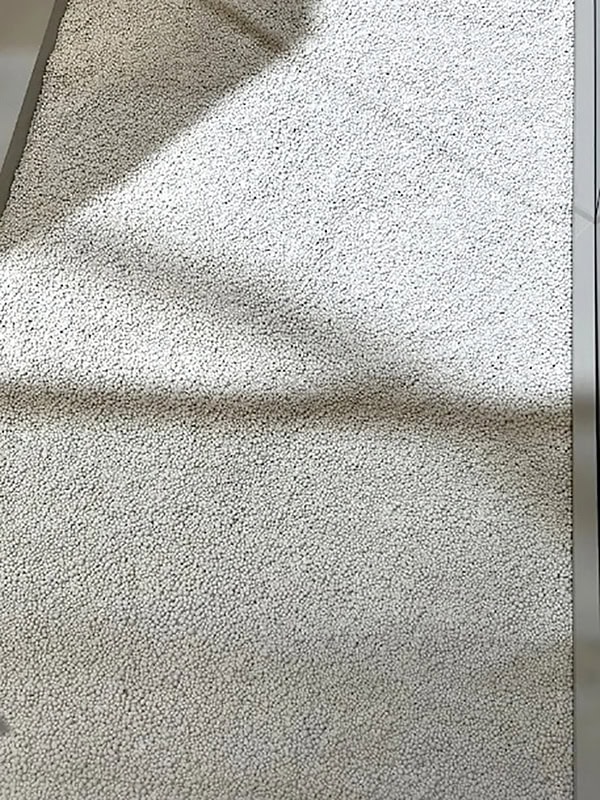

Figure 6 • Outer (left) and inner (right) view of a perlite-core vacuum insulation panel.

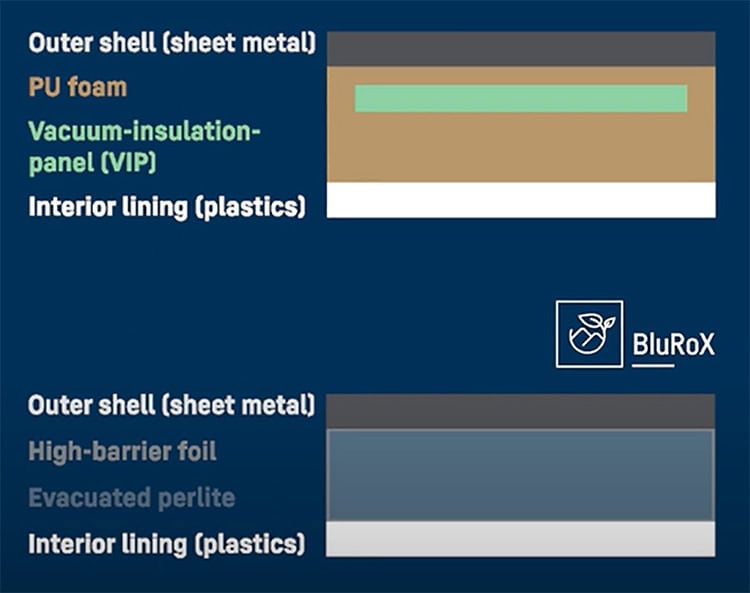

Figure 7 • Traditional design (top) versus the innovative BluRoX’ freezer wall containing evacuated perlite.

Expanded Perlite in VIPs

Perlite is used in VIP cores as a cost-effective thermal insulation material. The following render expanded perlite a competitive material in that field:

- Low thermal conductivity: Expanded perlite has low thermal conductivity, thus reducing heat transfer through the panel.

- Lightweight: As a lightweight material, perlite use in VIP cores is beneficial for handling, transportation, and installation of the panels.

- Cost-effective: Compared to other competitive insulating materials used in VIPs core, like fumed silica, perlite is significantly cheaper. As a result, perlite is an attractive choice for reducing the overall cost of VIPs while also maintaining good thermal performance.

- Reduction of radiative heat transfer: Perlite scatters and absorbs infrared radiation, causing the overall reduction of radiative heat transfer within the panel which helps to improve the thermal resistance of the VIP.

- Fire safety: Perlite is incombustible, thus reinforcing the fire resistance of the panel, which is particularly important in building applications where fire safety is significant.

- Market supply: Expanded perlite is widely available, having a robust and widespread supply, which ensures for undisrupted distribution.

Perlite in Refrigerators

In 2023, Liebherr introduced a series of domestic fridge freezers employing a vacuum and lava stone, or expanded perlite, as an energy-efficient and recyclable insulation. The innovative technology takes advantage of the low thermal conductivity of perlite and its exceptional behavior under vacuum conditions. With the new insulation modules, the company achieved class A energy efficiency and 30% more freezer capacity retaining the same size because of the reduction of the insulation thickness [9].

BIBLIOGRAPHY

[1] Božicek, D.; Peterková, J.; Zach, J.; Košir, M. Vacuum Insulation Panels: An Overview of Research Literature with an Emphasis on Environmental and Economic Studies for Building Applications. Renew. Sustain. Energy Rev. 2024, 189, 113849, doi:https://doi.org/10.1016/j.rser.2023.113849.[2] Verma, S.; Sara, A.; Singh, H. Why and Which Opacifier for Perlite Based Vacuum Insulation Panels (VIPs) in the Average Temperature Range of 10–70 °C. Int. J. Therm. Sci. 2023, 186, 108136, doi:https://doi.org/10.1016/j.ijthermals-ci.2022.108136.

[3] IEA/ECBCS Vacuum Insulation Panels: Study on VIP-Components and Panels for Service Life Prediction of VIP in Building Applications; 2005.

[4] Simmler, H.; Brunner, S. Vacuum Insulation Panels for Building Application. Energy Build. 2005, 37, 1122–1131.

[5] Alam, M.; Singh, H.; Limbachiya, M.C. Vacuum Insulation Panels (VIPs) for Building Construction Industry – A Review of the Contemporary Developments and Future Directions. Appl. Energy 2011, 88, 3592–3602, doi:https://doi.org/10.1016/j.apenergy.2011.04.040.

[6] Kan, A.; Zhang, X.; Chen, Z.; Cao, D. Effective Thermal Conductivity of Vacuum Insulation Panels Prepared with Recyclable Fibrous Cotton Core. Int. J. Therm. Sci. 2023, 187, 108176, doi:https://doi.org/10.1016/j.ijthermalsci.2023.108176.

[7] Alam, M.; Singh, H.; Limbachiya, M.C. Vacuum Insulation Panels (VIPs) for Building Construction Industry – A Review of the Contemporary Developments and Future Directions. Appl. Energy 2011, 88, 3592–3602, doi:https://doi.org/10.1016/j.apenergy.2011.04.040.

[8] Shi, M.; Yang, L.; Chen, Z.; Kan, A.; Chen, S.; He, T.; Zhang, J. Impacts Investigation of Gas Barrier on Effective Thermal Conductivity and Service Life of Vacuum Insulation Panel. Sci. Rep. 2023, 13, 20055, doi:10.1038/s41598-023-44929-3.

[9] BluRoX-Our Vacuum Perlite Technology Innovation Available online: https://doi.org/10.1007/978-1-4757-0528-7_52 (accessed on 10 September 2024).

To download a .pdf of the Perlite Cores in Vacuum Insulation Panels brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright © 2024 Perlite Institute All Rights Reserved