This transit mixing information is presented as a guide to eliminate some of the questions that may arise in the field and to ensure successful construction with perlite concrete.

The physical characteristics of expanded perlite lends itself to a variety of special purposes—including use as a constituent of lightweight concrete. For a detailed explanation of perlite expansion see info-sheet: Why Perlite Works.

Description

Perlite Concrete can be sub-divided into two categories:

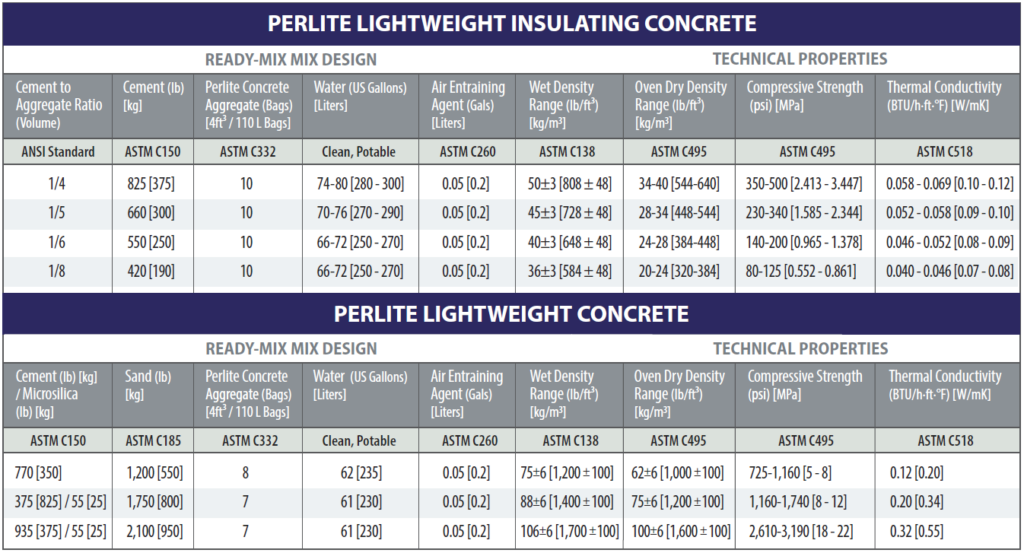

- Perlite Ultra-lightweight Concrete (densities less than 50 lb/ft³, or 800 kg/m³) is a mixture of perlite concrete aggregate combined with Portland cement, air-entraining agent and water. It is used for insulating roof decks, raised beds, curtain wall systems, LNG tank roof insulation and other permanent insulation applications.

- Perlite Lightweight Concrete (densities from 50-110 lb/ft³, or 800 – 1,800 kg/m³) is a mixture of perlite concrete aggregate combined with Portland cement, sand (micro-silica), air-entraining agent, superplasticizer and water. It offers high compressive and flexural strength and is suitable for floor fills and direct application of the final floor finishes. An air entraining agent is used to improve the workability and act as a density regulator (as well as maintaining insulation value). The use of a super plasticizer can reduce water to cement ratio for perlite concrete and increase the 28-day compressive strength.

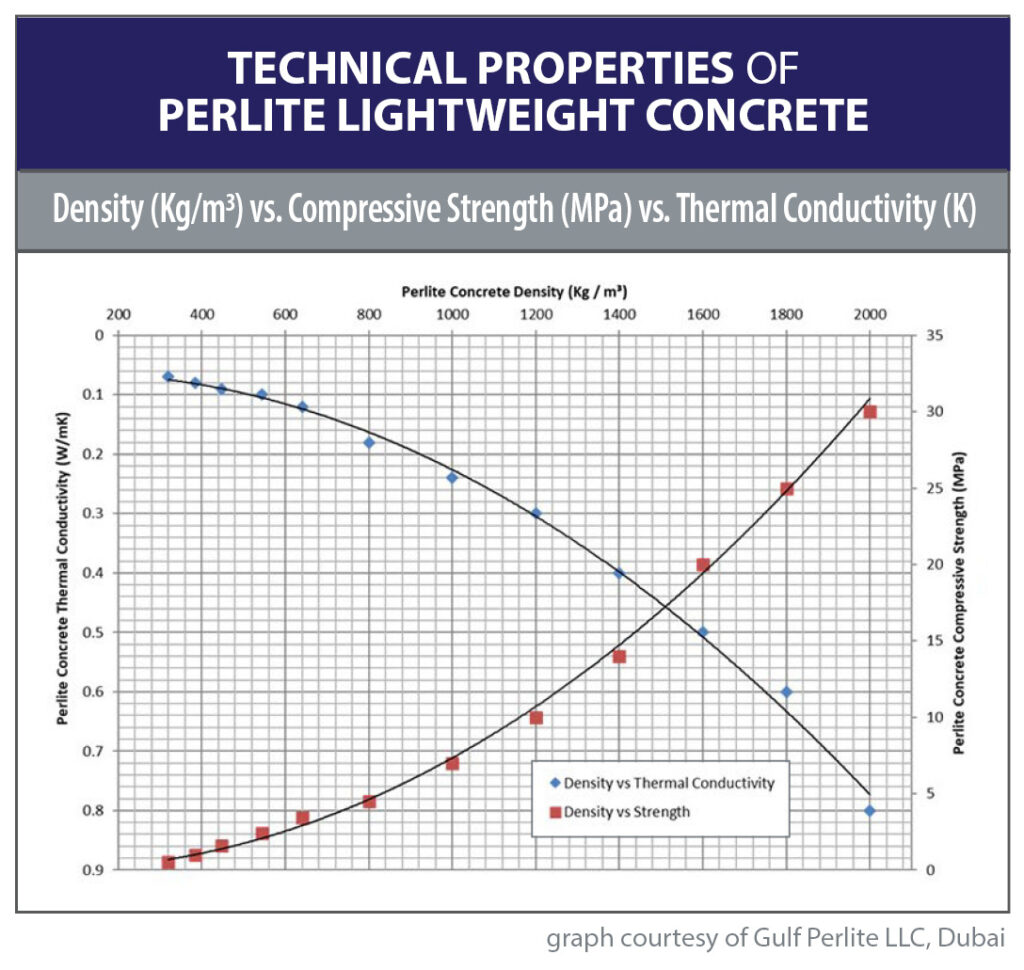

The graph below illustrates the achievable technical parameters of Perlite Lightweight Concrete at varying densities. Architects and engineers can use this guide as a reference to specifying Perlite Lightweight Concrete.

Mixing Perlite Concrete

While perlite concrete is mixed in the same equipment (batching plants and transit mixers) and by similar methods as ordinary concrete, there are some considerations that must be given to the order of addition of materials and to the time of mixing to assure correct concrete properties and adequate yield. The following mixing information for transit mixing is presented as a guide to the manufacturer to eliminate some of the questions that may arise in the field and to ensure successful construction with perlite concrete.

Transit Mixing

When transit mixing perlite concrete for the first time, it is suggested that the perlite manufacturer be consulted for suggestions as to the correct mixing time and procedure. These may vary with the type and age of available equipment.

Standard Mixing Procedure:

- Determine the load of the transit mixer.

- Add the correct amount of water (or add ice) to the plant mixer.

- Add the correct amount of cement and air entraining agent to the plant mixer and mix until a slurry is formed. (Refer to the manufacturer’s guide for correct dosage of air entraining.) Sand and microsilica may be added as per the mix design to achieve the perlite concrete specification.

- Discharge the full quantity of material constituents from plant mixer to transit mixer.

- Manually add (or convey via a silo system) the correct amount of perlite concrete aggregate to the transit mixer. Minimal rotations per minute shall be used when adding the perlite. During transportation do not rotate the drum.

- Upon arriving at the job site, mix at top speed for not less than 4—nor more than 6—minutes.

- Discharge in a normal manner after checking wet density for conformance to specification.

- Rotate the drum at idle speed when discharging the last of the load to ensure complete discharge of the concrete.

- Do not wash out the drum between loads. Use the same trucks throughout the job.

Perlite concrete aggregate particles are fragile and over-mixing will cause the perlite to pulverize, resulting in a loss of yield.

Care must be taken to ensure proper mixing time for perlite concrete. With the use of the correct amount of water and when properly mixed, the perlite concrete should have a slump of approximately 7-9 inches (180-220 mm) and may appear too wet by normal concrete practices. However, if the mix appears too dry or stiff, the mixing time has probably been too short. Continue mixing until the desired plasticity is reached. Extra water and under-mixing may reduce the yield and strength. The use of a superplasticizer can be used for mixes including sand to reduce the water requirement.

The first truck load of perlite concrete will usually discharge about one third of a yard (approx. 0.25 m³) short since this quantity will coat the inner walls of the truck drum. However, this will not occur in subsequent loads, because the walls will be coated sufficiently. After discharging the last load, 7-10 gallons (26-38 liters) of water may be added to the revolving drum to wash out this coating and this mixture may be dumped and blended with other concrete from the previous load. This will not impair the perlite concrete properties because the excess water bleeds out without loss of cement.

Wet Density

The wet density of perlite concrete as poured is important in the control of the physical properties of the dry concrete and to the yield achieved. The strength and the insulating value depend on the wet density of the perlite concrete. Heavier density means greater strength and less insulation. To achieve the desired characteristics, the architect or engineer usually specifies the wet density with tolerance of plus or minus 3 lb/ft³ (48 kg/m³).

Field Control

The wet density can be checked for conformance to the architect’s specifications beginning with the first truck load delivered. Adjustments to the mixing procedure should be made at that time and additional checks made periodically during pouring. The simplest method of field checking wet density is as follows:

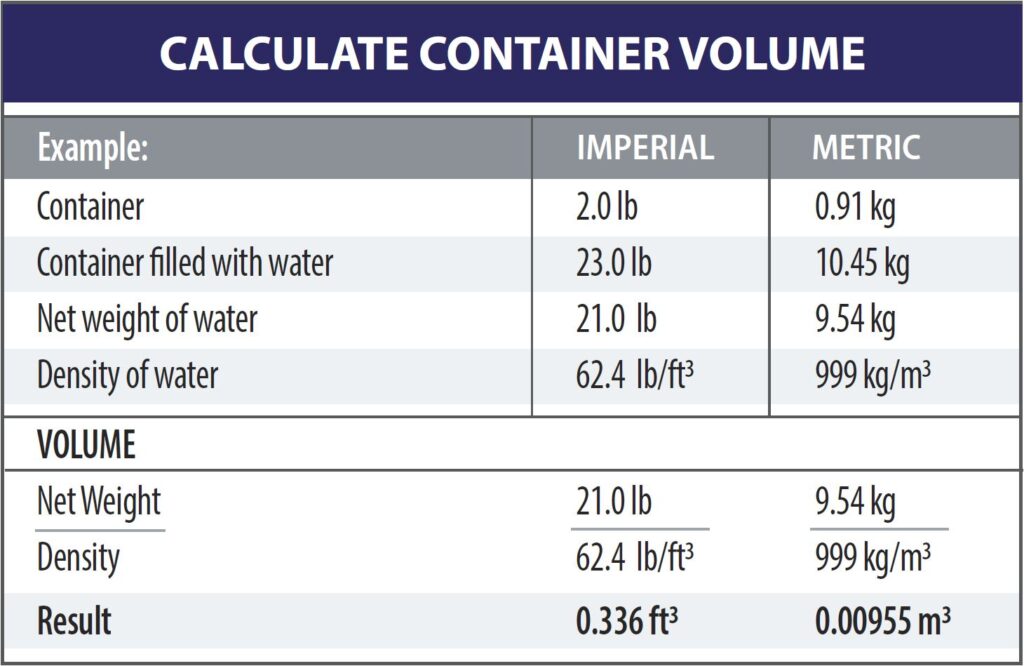

1. Calculate the volume of a container

Determine the exact volume of a cylindrical container such as a rigid 10-quart (10 liter) container. This can be done by first weighing the empty container, then filling it level full with water and weighing it again and subtracting the two weights. This provides the net weight of the contained water, and, if divided by the density of water, the result is the exact volume in the container.

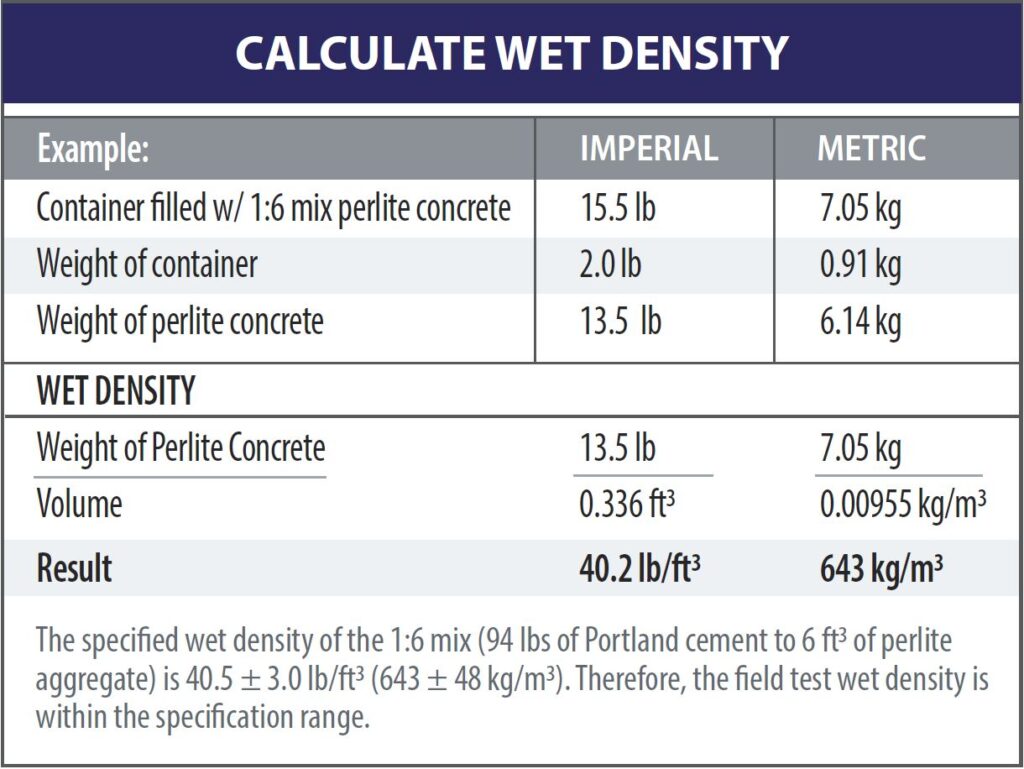

2. Calculate the wet density

Fill the container with wet perlite concrete as it leaves the mixer and weigh again. Subtract the weight of the empty container and divide the remainder by the volume as determined in Step 1. The result is the wet density of the perlite concrete in pounds per cubic foot which should be within ± 3 lb/ft³ (48 kg/m³) of the specified value.

Air Entraining Agent

The use of the correct amount of air entraining agent of the proper concentration is of extreme importance in successful perlite concrete construction. The air entraining agent produces countless tiny air bubbles in the concrete, which improves workability during placement, reduces the density, increases the yield and contributes to the insulation value of the dry concrete. Air entrained concrete is also more resistant to water absorption. Care should be taken in mixing perlite concrete to ensure that the proper amount of agent is used. Excess air entraining reduces the strength of concrete. An even distribution of agent is also essential to produce the desired concrete characteristics. Follow the manufacturer’s recommendation with respect to dosage of air entraining agent.

Super Plasticizer

The use of Super Plasticizer (SP) can reduce the water to cement ratio and enhance the strength of the concrete for mixes with sand. SP can improve workability, speed finishing, increase strength, conserve cement and help reduce shrinkage and thermal cracking. Follow the manufacturer’s recommendation for the correct dosage of SP. Do not overdose as this will adversely affect concrete strength and cause segregation.

Placement of Perlite Concrete

Perlite concrete may be placed with a crane and bucket or by pumping. Use of a rotor/stator (progressive cavity) pump—as opposed to a piston pump—is recommended as this type of pump will not place undue pressure on the perlite. Although not recommended, perlite concrete with a density above 1,000 kg/m³ may be pumped using ready-mix pumps if low pressure is maintained. Care should be taken with respect to yield. In addition, a pump hose should be a minimum of 3 inches in diameter. Avoid hose kinking. Hoses should be tied off at each joint.

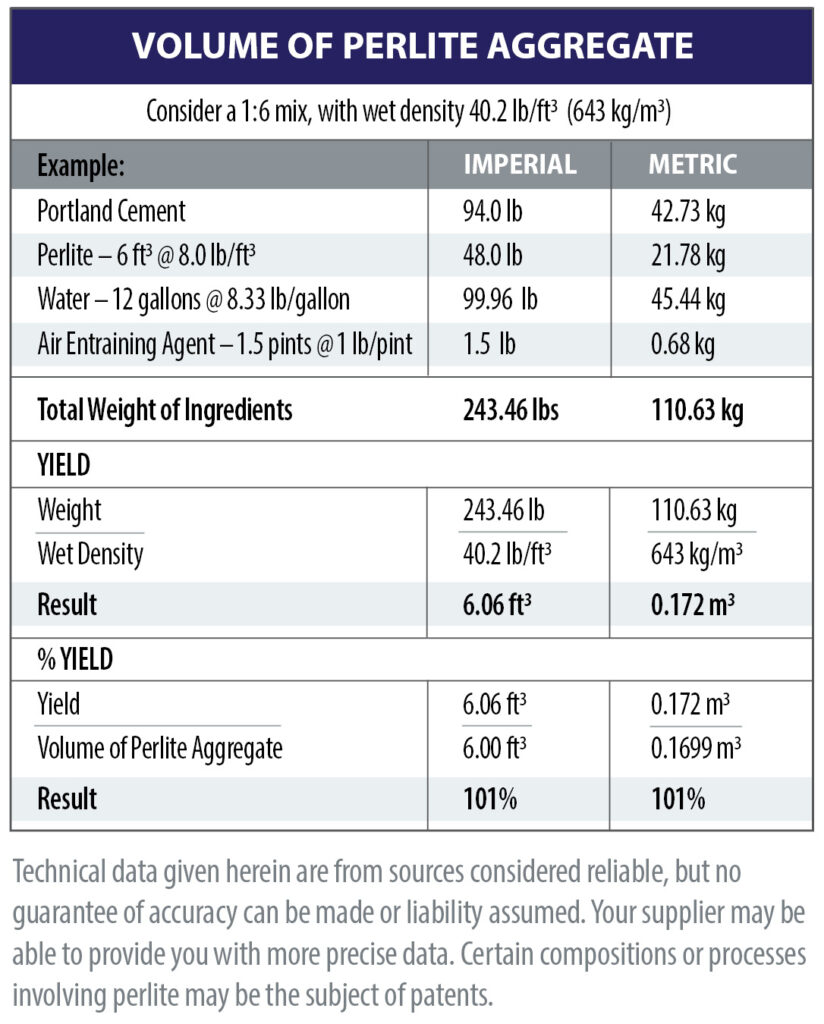

Yield

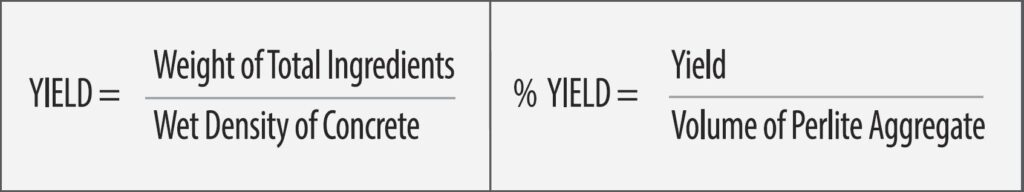

Yield is defined as the ratio between the volume of the wet perlite concrete as discharged from the mixer and the volume of perlite concrete aggregate used in the mix. The mix proportions included in the specifications are based on extensive field and laboratory tests and are established for 100% yield. If the correct quantities of material and mixing procedure are used, a 100% yield should result. Yield may vary however as it is affected by job site conditions including mixing time, fineness of aggregate, pumping equipment, height to be pumped, length of hose, etc.

Field Check for Yield

The first step necessary in making a field check for yield is to determine the wet density of the perlite concrete as previously outlined. The wet density and the weight of total ingredients for the mix being used are then substituted in the following formula:

Loss of Yield

If the yield as checked by the wet density is less than 100%, a loss of yield is evident. A loss of yield may be attributed to a number of factors as previously noted. However, one or more of the following factors should be checked.

Air Entraining Agent – Be sure that the proper amount is being added to each batch. Check concentration.

Mixing Procedure and Time – Be certain that materials are added in the proper sequence. Undermixing will usually result in loss of yield while overmixing can adversely affect the air entrainment.

Water – Check the amount of water being added. After one minute of mixing, properly proportioned perlite concrete often looks too dry. If extra water is added, yield can be reduced. Hard water will often offset the effect of the air entraining agent and may require adjustment of the quantity of air entraining agent.

Mix Design Data – The proper proportions of materials for various perlite concrete mixes are shown in the table below. The importance of properly designing and specifying the mix and the proper use of the air entraining agent cannot be overemphasized.

To download a .pdf of the Transit Mix Perlite Lightweight Concrete brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright © 2019 Perlite Institute All Rights Reserved