Perlite, an inorganic material, is as permanent as the walls it insulates.

The physical character of expanded perlite lends itself to a variety of special purposes – including use as loose-fill masonry insulation. For a detailed explanation of perlite expansion, see information sheet: “Why Perlite Works“

PROPERTIES & BENEFITS

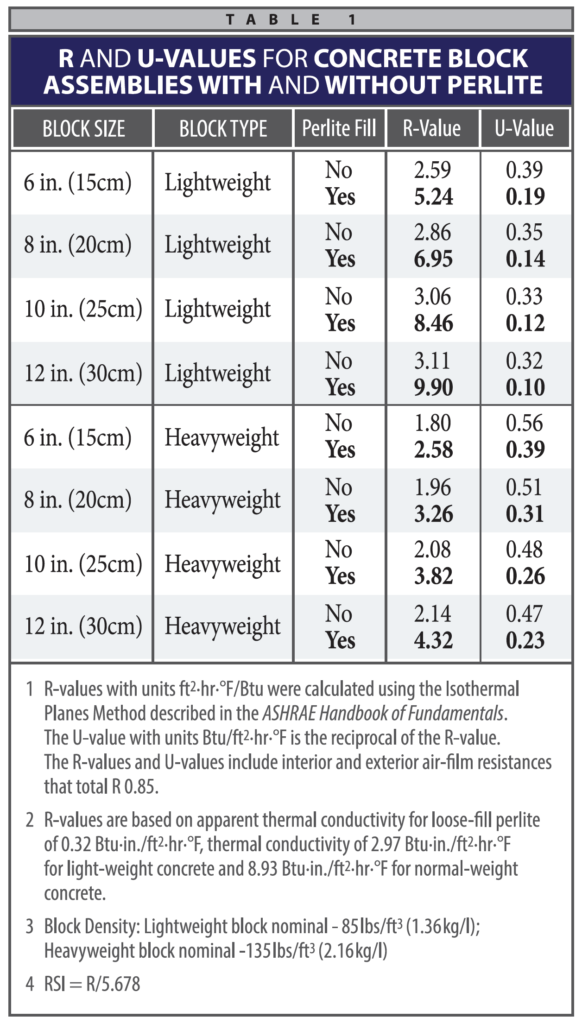

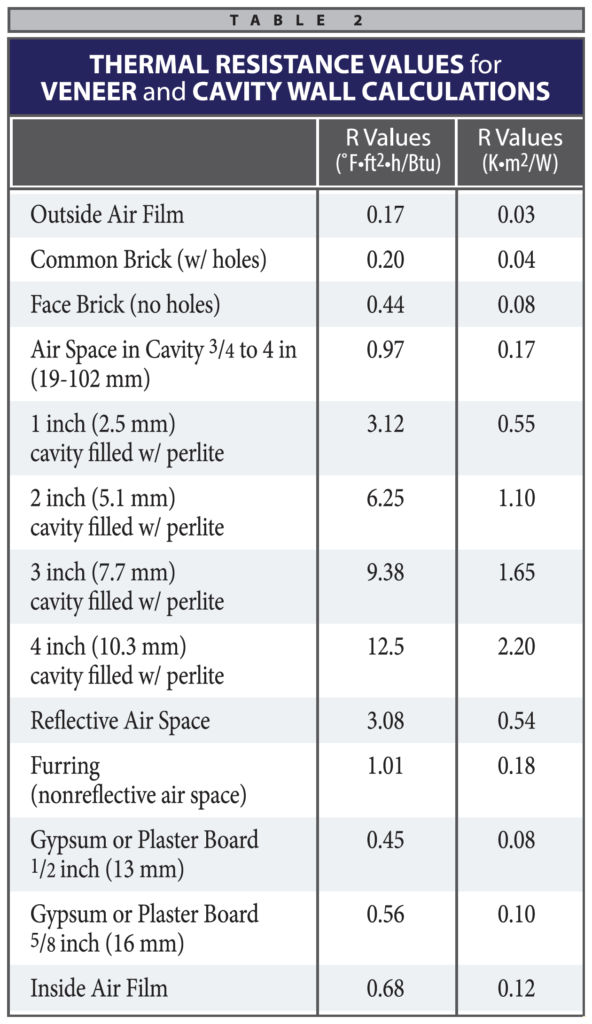

Insulation: Thermal performance tests have shown significant energy savings when perlite is used to fill the cavities in concrete masonry structures.

Standards, Specifications and References: Perlite is represented in the standards by ASTM product specification C549. The ASTM test methods used to evaluate loose-fill Perlite insulation are listed below.

- ASTM C549 “Specification for Perlite Loose-Fill Insulation”

- ASTM C520 “Test Methods for Density of Granular Loose Fill Insulations”

- ASTM C1363 “Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus”

- ASTM E 84 “Test Method for Surface Burning Characteristics of Building Materials”

- ASTM E 136 “Test Method for Behavior of Materials in a Vertical Tube Furnace at 750°C”

Non-Combustible: Perlite attributes –

- The temperature range for perlite fusion is 2,300-2,450°F (1,260-1343°C).

- Perlite is a Class A, Class 1 building material

- Flame spread 0; Smoke density 0

4 Hour Fire Ratings: Underwriters Laboratories Design No. U905 shows that a 2 hour rated 8, 10, or 12 inch (20, 25, or 30 cm) concrete block wall is improved to four hours when cores are filled with perlite. UL Designs U901, U904, and U907 also achieve 4 hour fire ratings.

Permanent: Perlite is an inorganic, naturally occurring mineral and is as permanent as the walls which contain it. It supports its own weight and will not settle or bridge.

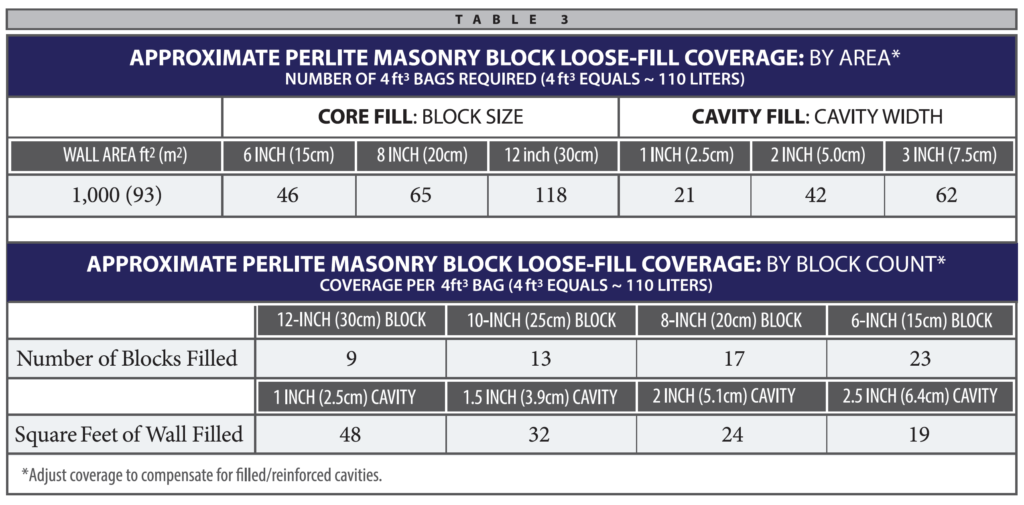

Economical: Perlite loose-fill masonry insulation offers excellent thermal and fire resistant properties at an economical cost. It is lightweight and pours easily and quickly without requiring special equipment or skills.

INSTALLATION GUIDE

GUIDELINES FOR USE:

Materials

It is recommended that the loose-fill perlite shall conform to the requirements of ASTM Designation C549. Ask your supplier to provide documentation that the product conforms to ASTM C549 Standard Specification for Loose Fill Insulation.

Installation

- The loose-fill perlite should be installed in the following locations:

a. In the cores of all exterior (and interior) hollow masonry wall.

b. In the cavity between all exterior (and interior) masonry walls.

c. Between exterior masonry walls and interior furring. - The loose-fill perlite should be poured directly (or via a hopper) in the top of the wall at any convenient interval (not in excess of20ft [6m]). Wall sections under doors and windows should be filled before sills are placed. Rodding or tamping is not recommended.

- All holes and openings in the wall through which loose-fill perlite can escape should be permanently sealed or caulked prior to installation. Screening should be used in all weep holes. (The inclusion of weep holes is considered good construction design practice to allow passage of any water which might penetrate the cavities or core spaces of wall construction.)

- The loose-fill perlite must remain dry. Suitable means should be used as the work progresses to insure that the insulation is protected from inclement weather.

To download a .pdf of the Perlite Loose-Fill Masonry Insulation brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright© 2013 Perlite Institute All Rights Reserved