Ceiling tiles, pipe insulation, and fire-rated door cores are examples of products that attain lightweight bulk from expanded perlite.

The physical character of expanded perlite lends itself to a variety of special purposes including the use in lightweight formed products. For a detailed explanation of perlite expansion, see information sheet: “Why Perlite Works” in the information library.

Over half of all the perlite expanded in the United States annually is used to make “formed products.” These products include ceiling tiles, pipe insulation, roofing board and fire-rated door cores, and are manufactured with a variety of binders.

Perlite formed products are the combination of perlite granules with binders such as fibers, hydraulic cement, plaster, sodium silicate, or even asphalt. These binders give the granules a portable, durable shape suitable for an intended use. The use of sodium or potassium silicate binders is discussed below. Other binders are simply blended with the perlite, and water, if needed to activate the binder, and then placed in a suitable mold.

Perlite/Silicate Composites

Liquid sodium silicates (waterglass) are used as binders in many of the above applications. These sodium silicate binders are solutions of water soluble glasses manufactured from varied proportions of soda ash and silica, providing a wide range of chemical and physical properties. Sodium silicates are widely used as high temperature adhesives and binders due to the following properties:

- Low cost

- Inorganic

- Easy to handle

- Rapid controlled set

- High strength

- Insolubility (when cured)

- Chemical Stability

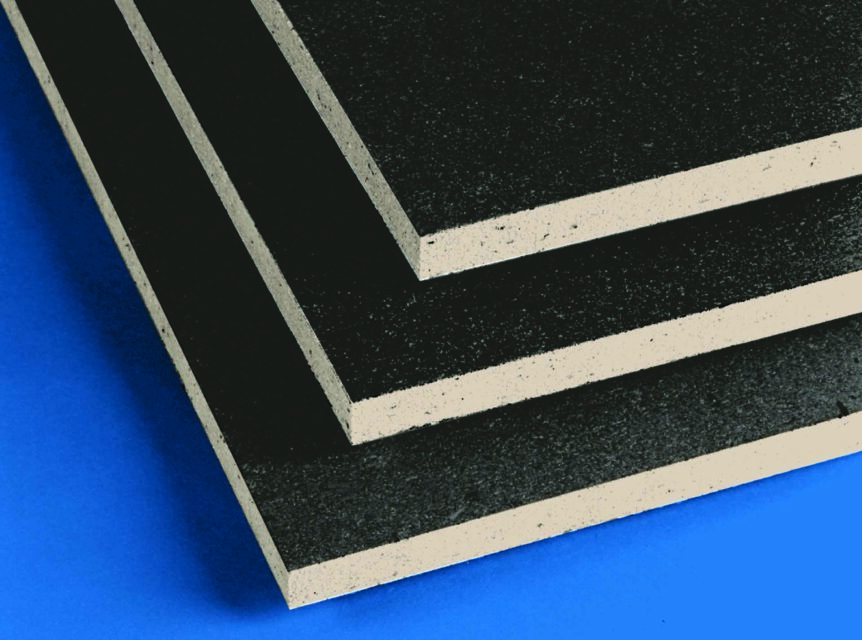

Fesco brand insulating roof board from Johns Manville Corp.

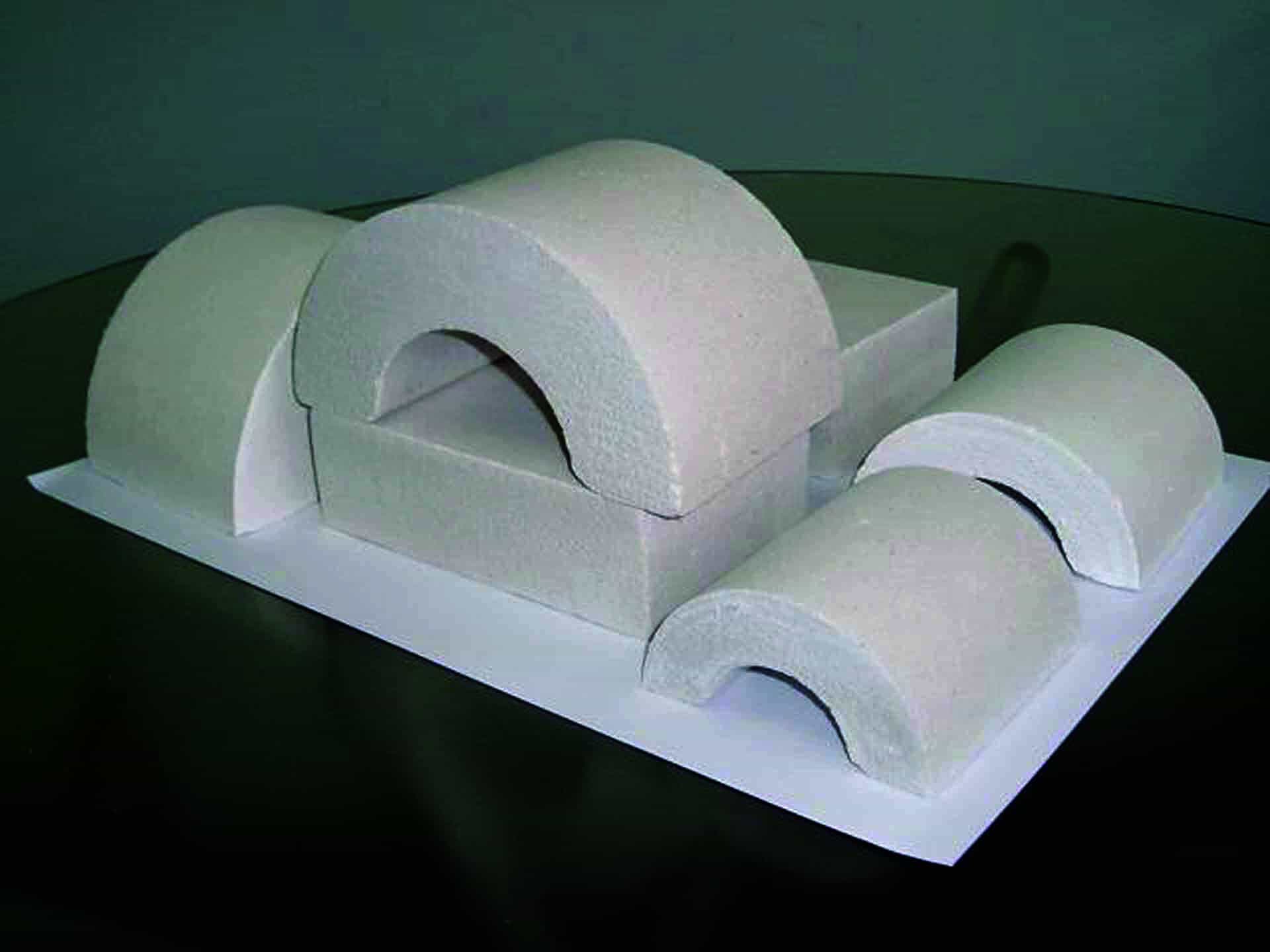

Temperlite brand pipe insulation from ITW Insulation Systems

Silicate-bonded perlite makes an insulation material which is completely non-flammable, the refractory nature of the bond being a major advantage. Potassium silicate is sometimes preferred for applications where heat insulation and fire resistance are the main objectives. This material has a slightly higher softening point than its sodium counterpart. Sodium silicate is widely used as a binder for molding sand in foundries.

To download a .pdf of the Lightweight Formed Products brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright© 2012 Perlite Institute All Rights Reserved