Perlite offers a unique combination of outstanding physical properties and low cost relative to other alternatives, due to its manufacturing method and worldwide availability.

Golf greens rank among the world’s most highly engineered landscapes. According to the United States Golf Association (USGA), golf greens must provide performance and pristine playing conditions while under almost continual use and with minimal maintenance. Among the most important aspects to ensuring a green’s success is the infiltration rate. Greens must be able to absorb heavy moisture levels from rainfall or irrigation in a short amount of time, while resisting compaction and maintaining balanced air, water and nutrient conditions.

Specially composed soil containing sand and other amendments, such as perlite, is aimed at enhancing these aspects, and ensuring performance is properly maintained. Perlite, a glassy volcanic mineral, is composed of uniform granules with a porous, irregular surface that are durable, store water and nutrients, and allow for significant water savings with minimal investment.

While strictly sandy soil is the most commonly used substrate for golf courses, it offers limited water-holding capacity as a consequence of its particle and pore sizes. To address the problem, the addition of fine expanded perlite (0-1 mm) as a portion of the mixture significantly improves the performance of the substrate.

Advantages of Amending with Perlite

- Improved water-holding capacity (fine perlite holds as much as six times its weight or more in plant-available water).

- Improved permeability and aeration of the soil.

- No change to pH or electric conductivity (EC).

- Perlite is sterile, weed and pathogen free.

- Perlite offers long-lasting, consistent performance.

- Perlite is lightweight and easy to work with requiring no special heavy lifting equipment.

- Perlite is 100% natural, inert, odorless and non-toxic.

How Does It Work?

Perlite’s porous surface provides a large area that conducts water under saturated conditions. When drained, it is filled with air providing the necessary oxygen for root growth. Capillary porosity helps hold moisture against the force of gravity, retaining much of it for plant use. An 80/20 sand to perlite mixture provides equal distribution of air and water-filled pore space for free drainage. The lower uniformity coefficient of this mix improves compaction resistance. The result is a superior substrate, with consistent lasting benefits, and reduced maintenance and associated costs for facility management for years to come.

Improved Water Management

The addition of perlite has been shown to improve the water holding capacity of sandy soils. Precious irrigation water is not lost to deep percolation, resulting in a significant reduction in its consumption. Simply put, there is no other more effective water conservation method for turfgrass management.

Perlite has been used as an effective soil amendment for many years. In 1974, the Los Angeles Department of Recreation used perlite as an effective soil amendment to Encino, Griffith, Hensen Dam, and Woodley Golf Courses. Since then, numerous other golf courses worldwide, and especially in the Middle East, have been constructed to USGA specifications using perlite (see Tables 1 & 2 for specifications).

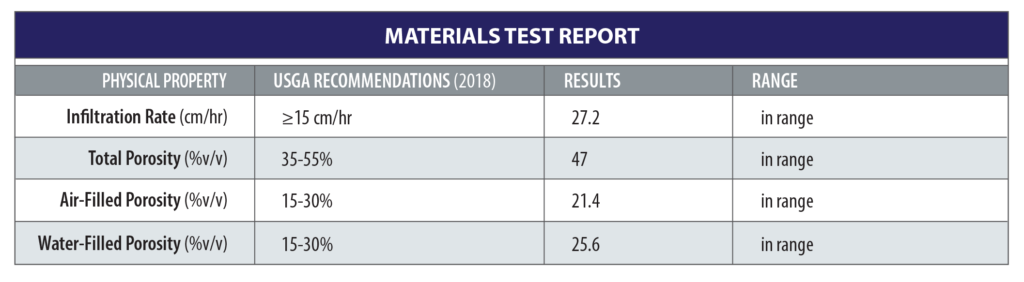

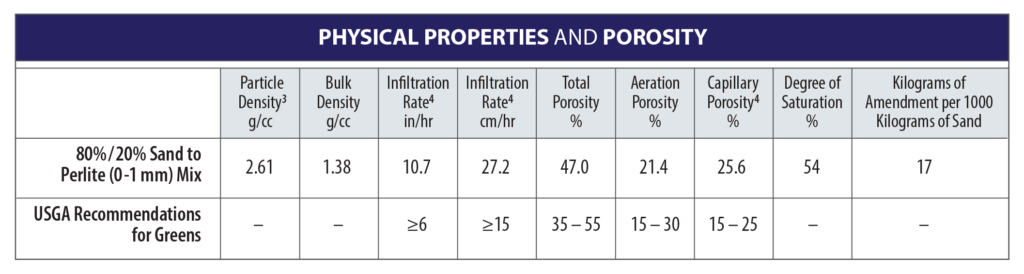

The use of USGA-approved soil mix with perlite at a recommended mix ratio of 20% by volume affected the technical properties of the soil profile in the following ways:

- Reduced soil mix bulk density

- Optimized infiltration rate

- Improved nutrient and water holding capacity

- Increased resistance to compaction

- Improved aeration contributing to healthy growth

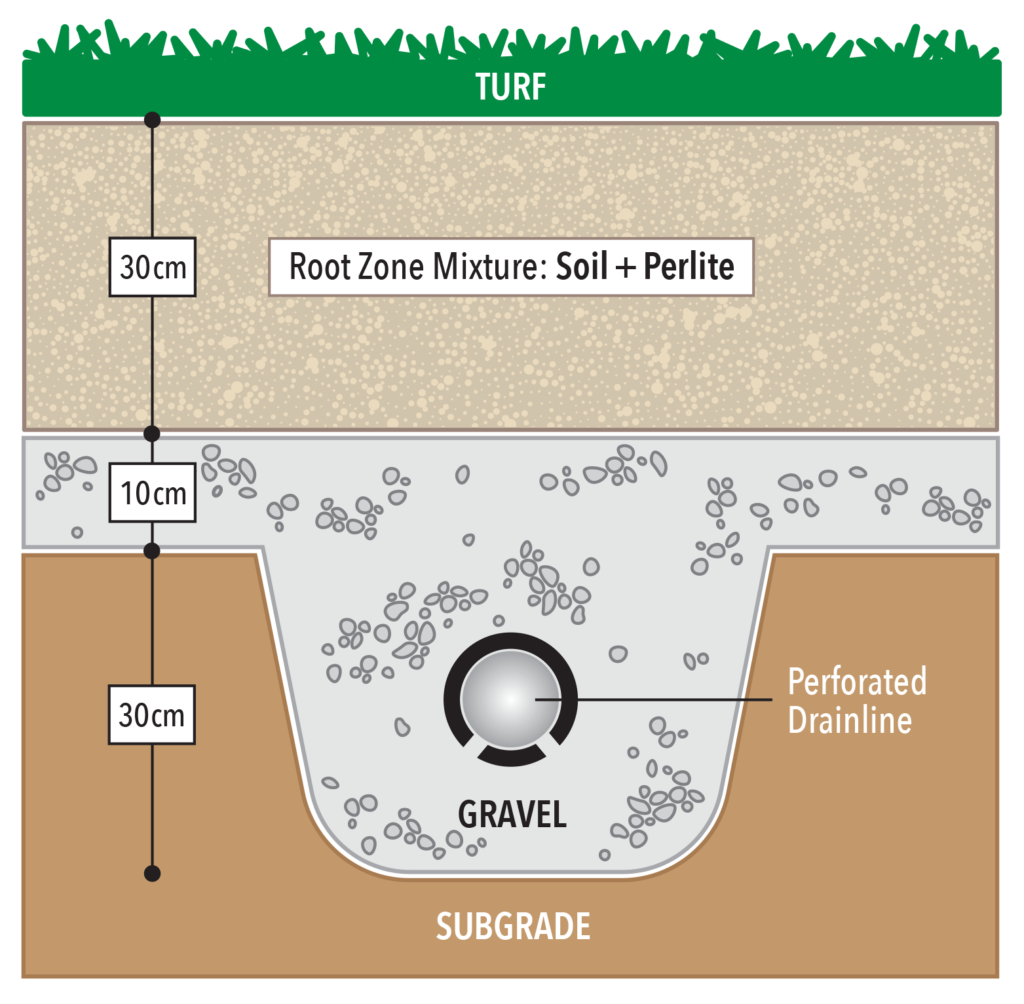

The root zone tension for a sand-perlite mixture at 30 cm (11.8 inches) depth satisfies the USGA recommendation for percolation rate, total, air-filled, and water-filled porosity. The use of perlite as a soil amendment for golf courses meets USGA (2018) requirements.

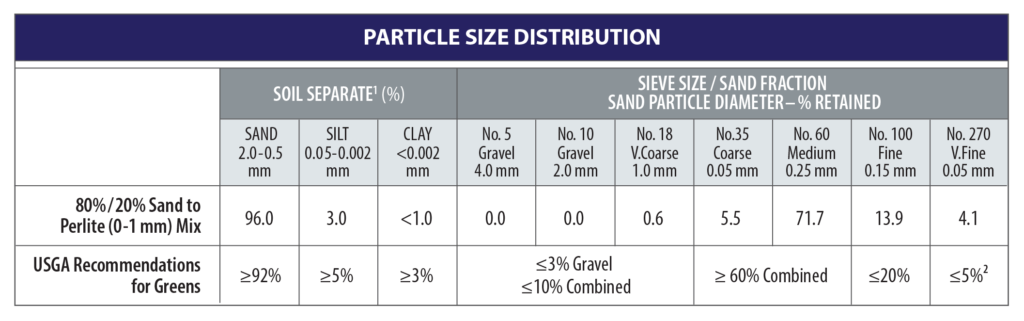

1 • ASTM F1632-03: Standard Test Method for Particle Size Analysis and Sand Shape Grading of Golf Course Putting Green and Sports Field Rootzone Mixes, ASTM International, West Conshohocken, PA 2012, www.astm.org

2 • Maximum of 10% combined on Very Fine Sand, Silt, and Clay fractions.

3 • ASTM D5550-14: Standard Test Method for Specific Gravity of Soil Solids by Gas Pycnometer, ASTM International, West Conshohocken, PA 2012, www.astm.org

4 • ASTM F1815-11: Standard Test Method for Saturated Hydraulic Conductivity, Water Retention, Porosity and Bulk Density of Athletic Field Rootzones determined at 30cm tension, ASTM International, West Conshohocken, PA 2012, www.astm.org

Golf Green Restoration Using Fine Perlite

Step 1: Existing sod removal

Use a sod cutter to remove existing sod and any possible thatch layer.

Step 2: Spread perlite over the substrate mix

Use a rake to make a uniform layer of perlite throughout the green.

Step 3: Thoroughly till perlite into the substrate

Use a tiller to incorporate perlite into the growth layer. Make the soil profile as uniform as possible by making several passes with the tiller.

Step 4: Compact and lightly contour the root zone to ensure surface drainage

Smooth and firm the surface to ensure surface drainage. To reduce future settling as much as possible, irrigate and roll the greens before seeding or replacing sod.

Step 5: Reestablish the golf green

Use turf varieties well suited for the climatic conditions. Carry out soil analysis for a basis of your fertilizer program.

Sand and perlite greens offer optimal physical characteristics for heavy traffic areas for years to come.

To download a .pdf of the Perlite for Golf Course Greens brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright © 2021 Perlite Institute All Rights Reserved