Efficiency-boosting precoat protects against blinding and increases air flow

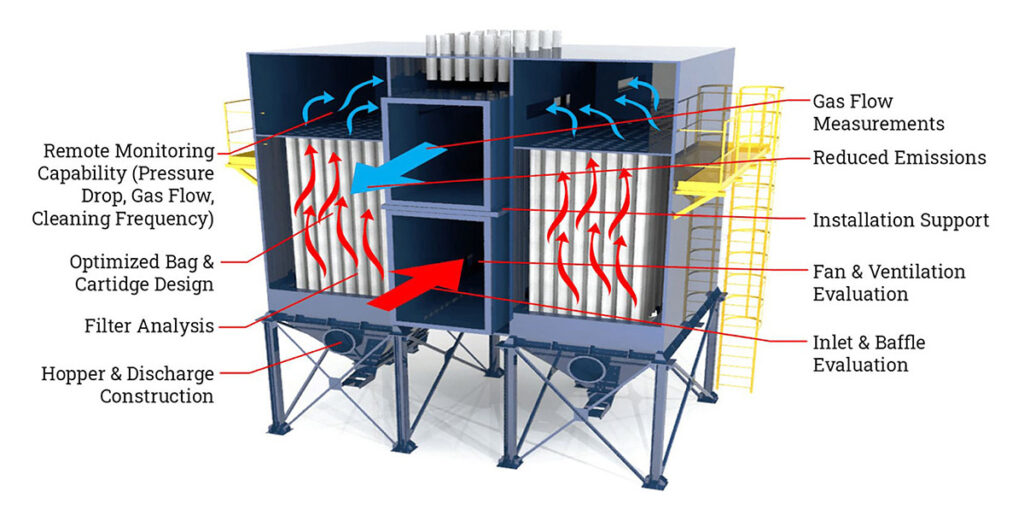

A baghouse dust-collection structure or device uses tubes, envelopes, or cartridges to gather dirt, particulate matter, and dust from the off-gases stream of a manufacturing or processing plant. Particulates separation from the air steam is carried out by separation media or bags. As filtration proceeds, the filtrate is accumulated on the filter cloth, forming a layer of increasing thickness, called dust cake. The development of the dust cake worsens the filtration conditions over time until it becomes so thick and large that it obstructs airflow and requires cleaning the bag filters. Most common cleaning techniques are the application of reverse air flow, bag shaking, and the application of pulse jet.

The Filter Bag

In a fabric filter unit, rows of fabric bags in the shape of flat, rounded, shaped tubes or pleated cartridges are housed in one or more isolated compartments. The stream of off-gas ascends and follows the surface of the bags before entering the cloth radially. The particles are retained on the upstream face of the bags, while the cleaned gas stream is released into the atmosphere. The filter is operated cyclically, going through relatively extensive filtering times interspersed with quick cleaning intervals. During cleaning, dust that has been accumulated on the bags’ fabric surface is taken off and stored in a hopper for later disposal.

Precoat

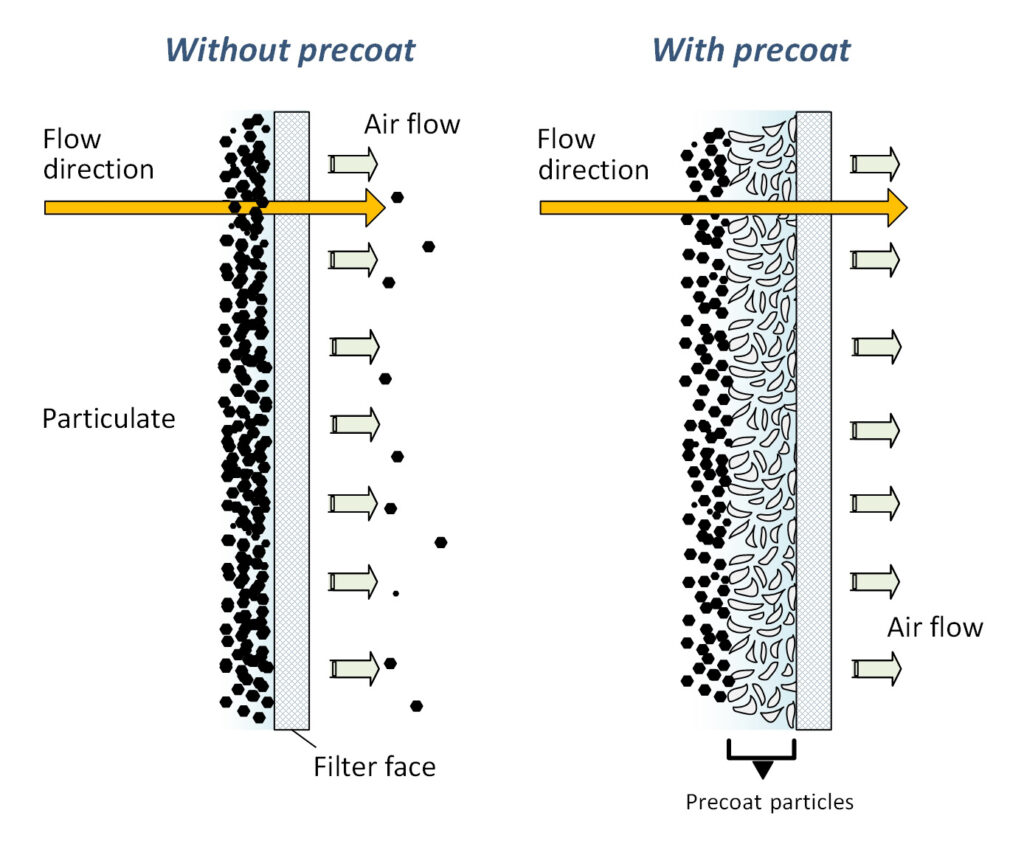

Precoat or precoat filter aid is a granular, chemically-inert and non-toxic powder that is used to coat and condition the fabric filters in baghouses, scoping the improvement of filtration efficiency and effectiveness. This is achieved by the establishment of a uniform, three-dimensional, porous cake on the filter face, consisting microscopically of a thick network of tiny channels that may accommodate particulate matter and in parallel provide with countless air escaping routes.

Perlite filter aid is an efficient precoat material that is usually used in two ways:

- New bags are pre-coated before they are used for the first time.

- Perlite is injected or added constantly during regular operations. The practice is similar to body feed technique that finds application in the filtration of liquid and pulps.

The amount of precoat utilized should be a minimum of 0.25 kg per m2 (1 lb per 20 ft2) of baghouse filter cloth area. For cartridge filters, 0.05 kg per m2 of media (1 lb per 100 ft2).

The following are some of the most significant benefits of using precoat filter aid in baghouse:

- Protects filter cloth from blinding and plugging

- Increases air flow

- Enhances fabric filter bag life and performance

- Decreases differential pressure

- Increases dust collection efficiencies

- Inhibits damaging sparks

- Absorbs damaging moisture, oils, and hydrocarbons

- Lessens operating and maintenance costs

APPLICATION INSTRUCTIONS

(by FabCo Industrial Services)1

The use of perlite filter aid for the specific application is carried out by applying these consecutive steps:

- Remove dust from bag house hoppers and turn off dust removal equipment.

- Deactivate bag cleaning cycle to avoid precoat removal.

- Operate system at approximately 50% of design air flow to the baghouse to achieve air flow velocity of approximately 10.1 m/s.

- Add precoat at a rate of 0.136 kg per min per 1000 ACFM (0.3 lbs per min per 1000 ACFM) of reduced gas flow to the baghouse.

- For baghouse operating under suction, precoat can be injected through ports or inspection doors in ducts or hoppers.

- For positive pressure baghouses, precoat should be injected into duct at the suction side of the positive pressure system fan.

- Isolate each compartment and inspect filter bags for adequate precoat cake (approx. 1 mm or 1/26″ thickness) and check inside of hoppers to be sure there is not a large amount of precoat dropout.

- Once filter bag precoating with precoat is complete, increase the air volume for normal design flow levels to the baghouse, and turn on the hopper dust removal equipment. However, do not reactivate the filter bag cleaning cycle until a minimum differentia pressure of 7.6-10.2 cm (or 3″-4″) static pressure water gauge is measured across the bags. This ensures that a seasoned cake of precoat has been achieved on the filter bags prior to activation of the initial cleaning cycle.

1 • https://www.fabcoind.com/dust-collector-accessories/precoating

OTHER RELEVANT PUBLICATIONS FROM THE PERLITE INSTITUTE

Available for free at www.perlite.org/library

- Perlite Filter Aid (PFA) for Vacuum & Pressure Filtration

- Perlite Filter Aid and the Circular Economy

- Explained: Perlite Filter Aids

- Perlite for Filtration

To download a .pdf of the Precoat for Baghouse Fabric Filters brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright © 2024 Perlite Institute All Rights Reserved