Fully natural and chemically inert, perlite is affordable and highly effective for removing contaminates from pool water.

Filtration is one of the most widely applied techniques for the removal of insoluble contaminates from recreational pool water. Fully natural, lightweight and chemically inert, perlite filter aid offers a high performance, yet cost effective, method for the removal of microbes, bacteria, and suspended solids.

WHY PERLITE FILTER AID?

- Excellent filtration performance

- Superior precoating ability

- Significant loading capacity

- Easy, quick and complete cake release/removal

- Lightweight spent filter-cake

- Chemically inert, non-toxic, odorless, and environmentally safe

- Inherently resistant to chemical attack by chlorine or its compounds

Effective Filtration with Perlite

According to a 2012 study published in the Journal of Water and Health, traditional sand filters and cartridge filters have limited effectiveness when it comes to pathogen removal.[2] Microbes and bacteria active in recreational pools and spas pose a potential health risk to humans when their numbers grow too large. Due to their tiny size, pathogens such as these, require very fine filtration removal methods. This can only be achieved through the use of fine-grained filter media, such as a perlite filter aid.

Filter aids used in recreational water filtration can drastically improve the cleaning and disinfection of swimming pools, spas, and splash pads.

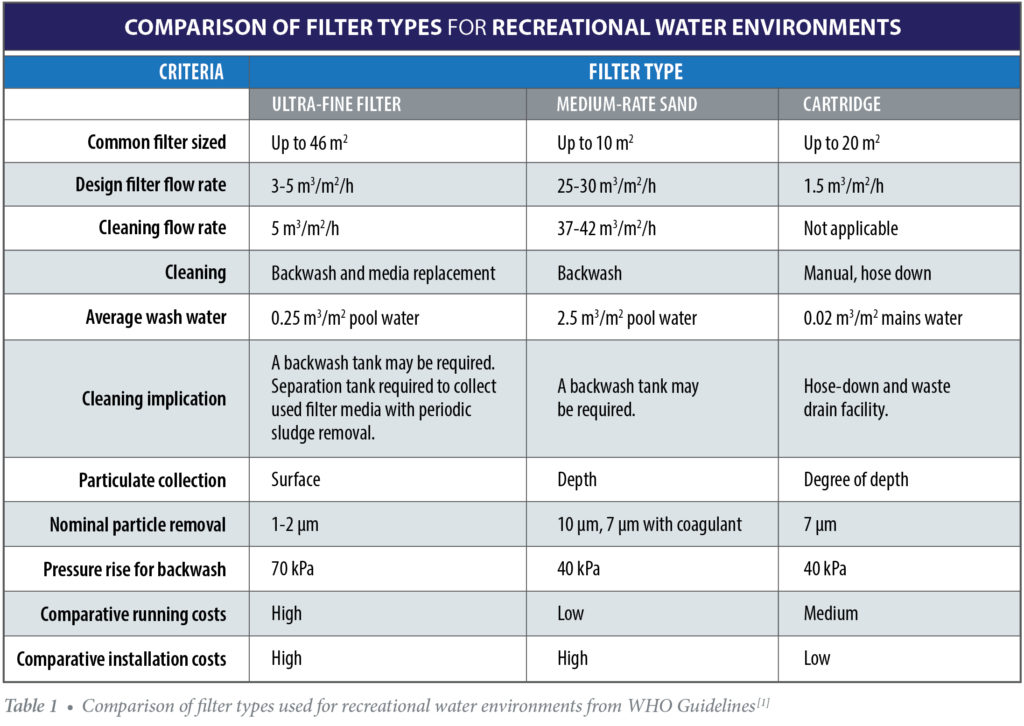

The World Health Organization (WHO) publishes a comparison of common filtration methods in terms of the performance, filtration efficiency and maintenance cost (Table 1).[1]

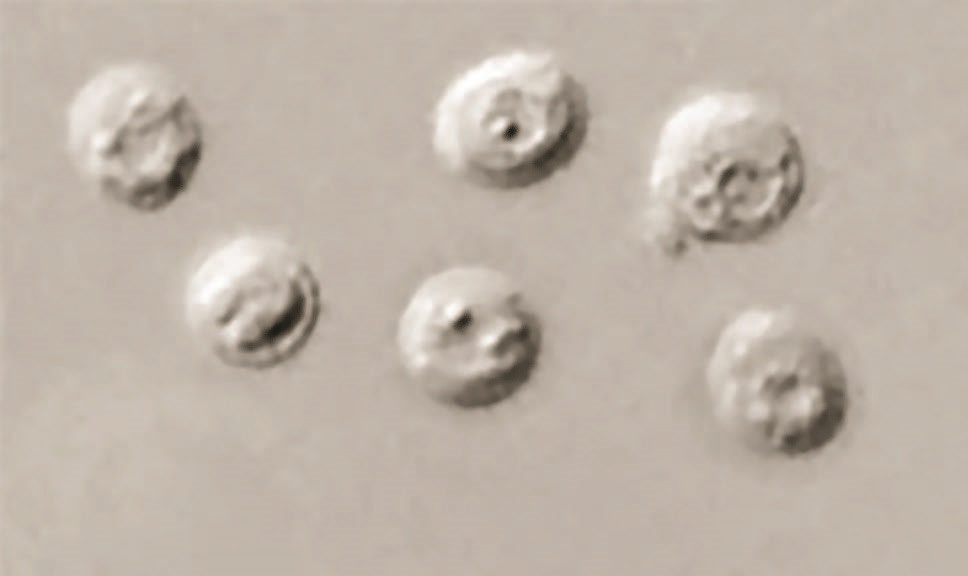

Of particular interest are Cryptosporidium oocysts and Giardia duodenalis. According to the WHO, Cryptosporidium oocysts are best removed by filtration media with pore spaces smaller than 4 μm (4/1,000s of a millimeter), while Giardia cysts may be removed by filters with slightly larger pore size of 7μm or less. Filtration offers a critical step in the removal of these pathogens from pools and spas. In fact, the use of fine expanded perlite resulted in the removal of more than 99.9% of Cryptosporidium oocysts. Perlite filter aid has also been found to be effective against microbes, notably, free-living amoebae that harbor opportunistic bacteria such as Legionella and Mycobacterium species.

Perlite Filter Aid

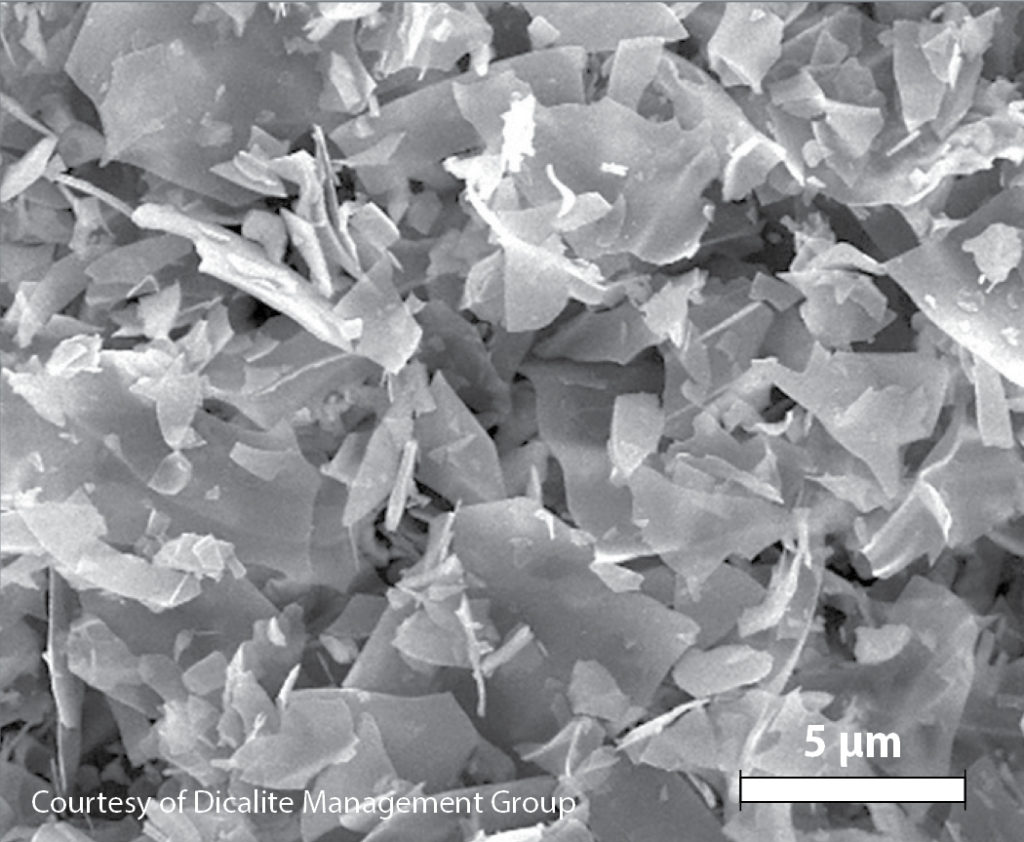

Perlite is derived from an amorphous volcanic rock (aluminosilicate) which in crude form contains 2-5% moisture by weight that is chemically bound in its structure. When perlite is rapidly heated to temperatures over 850 °C (1,600 °F), the combined moisture vaporizes and turns to steam, causing the creation of tiny glass bubbles 20 times the volume of the original starting particle size. The lightweight grains are then milled to produce tiny flattened particles that are classified into various filter aid grades according to size.

In addition to filtration for swimming pools and spas, perlite filter aid is widely used in purifying beverages, edible oils, and pharmaceuticals. The filter aid forms a porous layer on the septum that traps solids and prevents it from becoming clogged or blinded. Filter aid particles exhibit a jagged interlocking structure that present numerous microscopic channels when applied in a layer on the septum. Various perlite filter aid grades are available for a wide range of applications, or to achieve optimum flow rate and clarity.

A Case Study: Removal of Cryptosporidium

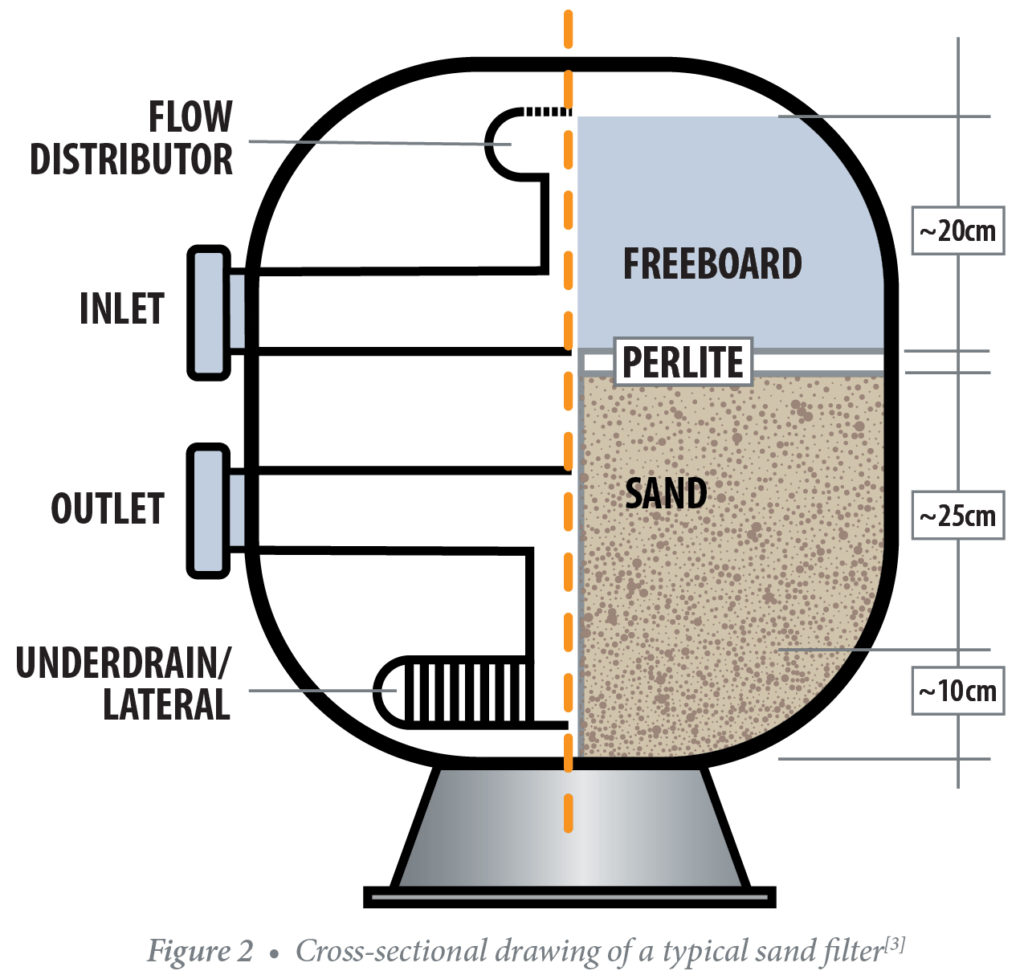

In a recent study, perlite filter aid was used in combination with a sand filter to remove Cryptospo-ridium-sized polystyrene microspheres from swim-ming pool water[3]. The use of a sand filter alone removed only 19% of the microspheres, while adding a thin layer of perlite (1.2 kg·m-2) resulted in a nearly 98% removal.

Oocysts of Cryptosporidium parvum, in wet mount, seen with differential interference contrast (DIC) microscopy. The oocysts are rounded, 4.2 to 5.4 µm in diameter.

DE Replacement

Diatomaceous Earth (DE) is a another mineral commonly used for liquid filtration. It is made from the fossilized remains of tiny, aquatic organisms called diatoms. Their skeletons are made up of a natural substance called silica. Over a long period of time, diatoms accumulate in the sediment of rivers, streams, lakes, and oceans. This material is mined and calcined (heated at high temperature) to destroy any organic matter. After the separate diatoms are agglomerated, the material is widely used as filter media. The level of agglomeration is controlled to achieve different flow rates. The diatomaceous earth is then milled and separated into various filter aid grades through the use of air classification. Due to the crystalline silica contained in calcined DE, the material has been classified as a Group 1 carcinogen by the U.S. Occupational Safety & Health Association (OSHA). Perlite filter aids are functionally like DE, however the different origin and physicochemical properties render perlite advantageous in the following ways:

DO MORE WITH LESS

Perlite has 30-50% less bulk density, thus comparable filter applications typically require 30%-50% less additive.

EASIER BACKWASHING

DE can build up where it is deposited and be difficult to remove. As a lighter product, perlite does not stick to the filter grids and bind them as easily, which makes the filter backwash easier.

FEW HEALTH CONCERNS

Contrary to DE, perlite filter aids generally contain no, or very little crystalline silica, thus only creates nuisance dust. Appropriate PPE is recommended.

NO DISPOSAL LIMITS

Due to its inert nature, perlite filter cake is not subject to the strict regulations governing its disposal.

EASY SUPPLY

Contrary to DE, a wide network of perlite suppliers is established assuring quick and uninterrupted local supply.

A Case Study: Use of Volcanic Glass in Filtration

Volcanic glass of rhyolitic composition has been used in gravity fed rapid filters for water treatment and its performance as filter media has been evaluated and compared to sand which is commonly used for such applications.[4];[5] Some interesting findings have arisen:

- The rate and the amount of wash water needed on the cleaning of the filter unit composed of sand is greater than for the bed composed of crushed volcanic material, because of the difference in densities involved.

- Durability tests show that similar to sand, natural glass is resistant to abrasion and/or attrition.

- Volcanic glass is suitable for the treatment of water containing high carbon dioxide content or high acidity, since it possesses lower solubility in acidic environments.

- In swimming pool environments, researchers noted as much as an 88% reduction in the amount of cleaning water needing to be replaced compared to traditional sand filtration, and that the replacement period could be extended to as much as twice the length of time as with sand filtration.

For more information on perlite filter aid and its application, see the Perlite Institute publications: Perlite Filter Aids Explained and Perlite for Filtration.

BIBLIOGRAPHY

[1] World Health Organization, “Guidelines for safe recreational water environments: Volume 2. Swimming pools and similar environments,” World Health Organization, vol. 2, no. January 2006, p. 146, 2006.[2] J. E. Amburgey, K. J. Walsh, R. R. Fielding, and M. J. Arrowood, “Removal of Cryptosporidium and polystyrene microspheres from swimming pool water with sand, cartridge, and precoat filters,” Journal Water Health, vol. 10, no. 1, pp. 31–42, 2012.

[3] J. E. Amburgey, “Removal of Cryptosporidium-Sized Polystyrene Microspheres from Swimming Pool Water with a Sand Filter with and without Added Perlite Filter Media,” Journal of Environmental Engineering, vol. 137, no. 12, pp. 1205–1208, 2011.

[4] S. S. Uluatam, “Laboratory evaluation of perlite bed filtration in water treatment,” International Journal Environmental Studies, vol. 42, no. 1, pp. 1–10, 1992.

[5] S. S. Uluatam, “Assessing perlite as a sand substitute in filtration,” Journal of American Water Works Assoc., vol. 83, no. 6, pp. 70–71, 1991.

[6] M. L. Christensen, M. M. Klausen, and P. V. Christensen, “Test of precoat filtration technology for treatment of swimming pool water,” Water Science Technology, vol. 77, no. 3, pp. 748–758, 2018.

To download a .pdf of the Perlite Filter Aid for Recreational Water Filtration brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright© 2021 Perlite Institute All Rights Reserved