Closing the loop through spent perlite filter cake reuse

Executive Summary

The circular economy targets the elimination of waste and the continual use of resources. This realizes mutual benefits to producers, consumers and the planet as a whole. The use of expanded perlite as filter aid is a well-established application that inevitably results in the production of a considerable amount of spent filter-cake. Contrary to conventional waste treatment (disposal), there are now a variety of reuse applications for spent perlite filter aid that do not require further treatment. This paper presents waste treatment methods that are capable of drastically eliminating filtration industry waste through reuse practices.

The Circular vs. Linear Economy

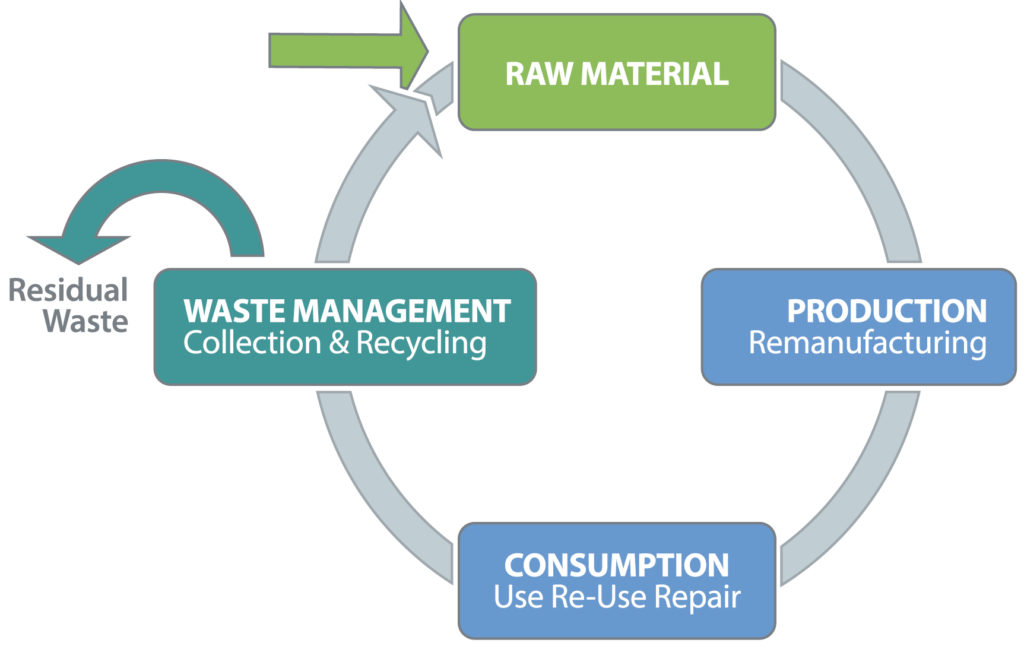

For many years, the economy took a linear “take, make and dispose” approach to resource use. Materials were extracted from the environment, manufactured into products, and then discharged as waste when no longer serving their useful purpose. Faced with increasingly strained resources and a growing impact on the environment, the world is now turning to more sustainable solutions. The so-called “circular economy” refers to an alternative vision where the value of products, materials and resources are maintained for as long as possible and waste is significantly reduced or even eliminated.

MAIN PRINCIPLES

- Design products with waste reduction in mind.

- Use products and materials for as long as possible.

- Recycle end-of-life products back into the economy to be used again.

PRIMARY BENEFITS[1]

- Economic benefits: new opportunities for growth and innovation, and savings related to improved resource efficiency.

- Reduced environmental impact: drastic reduction in greenhouse gas emissions.

- Improved resource security and reduced import dependence thanks to reduced demand for primary raw materials.

- Social benefits: ranging from new job creation across all skill levels to changes in consumer behavior leading to better health and safety outcomes.

Perlite Filter Aid

The use of expanded perlite as filter aid material is among the most important and dynamically growing application fields. This is attributed to perlite’s unique properties. For more detailed information on the use of expanded perlite as filter aid, see other publications on this subject on the Perlite Institute website: www.perlite.org. Examples include: Perlite for Filtration and Perlite Filter Aids Explained.

Reuses of Spent Perlite Filter Aid

Perlite filter aids are both sterile and inert and are used for filtering liquids in the beverage, food and pharmaceutical industries. No taste, color, or odor are imparted through their use; and perlite filter aids are deemed safe for their intended use as listed in the Food Chemicals Codex published by the United States National Academy of Sciences†.

† The Food Chemicals Codex is regarded as a source of information on the quality and purity of food grade substances, and is regarded as authoritative by many government agencies throughout the world.

ADVANTAGES OF PERLITE FILTER AID

- Low filter cake density (< 270 kg•m-3)

- High permeability

- Wide variety of properties (density, size, permeability)

- More economical filtration (same volume, half the mass)

- Less cake cracking and easy cake release

- Sterile and inert nature

- No health risk (non-toxic, non-carcinogenic and FDA approved)

- Safe handling and easy disposal

- Spent filter aid is reusable

ANIMAL FEED SUPPLEMENT

Expanded perlite has been widely tested as an animal feed supplement, proving that it is beneficial for animal digestion and breeding performance (i.e. weight gain, fattening period), for hogs[2], broilers and clucks[3]–[7] and fish[8]. In fact, spent filter aid issuing from the wine and beer industry contains valuable polyphenols, proteins and other substances that are beneficial for the breeding of animals, thus it is already common for it to be used as an animal feed ingredient[9].

COMPOST AND SOIL AMENDMENT FOR CROP PRODUCTION

Meunchang et al. investigated the composting of co-mingled filter cake and bagasse from sugar mills[10]. They focused on amount of time required for filter cake to compost to a stable product and the fate of nitrogen during composting. The researchers also looked at the effect of bagasse addition in the overall nitrogen loss during composting. The final compost materials appear to be suitable for use in agriculture, attaining suitable characteristics for pH, low phytotoxicity, freedom from pathogens as a result of the high temperatures developed during composting (50-60 °C). The resulting compost was also high in plant-available nutrients such as N (1.6–1.8%), P (1.2%), K (0.5%), Ca (10%) and Mg (0.5%). This practice is already in use elsewhere as evidenced by the Worchester Wine & Olive Route company[11].

PRODUCTION OF TARTARIC ACID

Among the most valuable uses for spent perlite filter cake is in the production of tartrate (a salt or ester or tartaric acid), resulting from processing the waste byproduct of wine and grape juice production. Tartare is used as an additive in food and pharmaceutical products. The amount and concentration of tartrate is reported to be between 100 to 150 kg per ton of wine grape lees, and 50 to 75 kg per ton of grape pomace[12]. Although tartaric acid is a valuable product in many industries, it is typically undesirable in wine production due to its detrimental effect on the quality of the wines being produced. Wineries flocculate tartaric acid using either calcium hydroxide or potassium hydroxide to obtain a stable finished product. A further filtration process then removes the undesirable precipitate. This waste byproduct, which contains high concentrations of calcium or potassium tartrate along with many other constituents (polyphenols, tannins, etc.), is then sold to factories which purify tartaric acid[13], a common practice in Australia’s wine industry today[14].

BIBLIOGRAPHY

[1] A. Reichel, M. De Schoenmakere, and J. Gillabel, “The Circular Economy in Europe,” European Environment Agency, 2016.[2] P. Glodek, “Perlite in hogs fattened feeds,” University of Gottingen, Germany, 1980.

[3] H. Talebali and A. Farzinpour, “Effect of different levels of perlite on performance of broiler chicks,” Int. J. Poult. Sci., vol. 5, no. 5, pp. 432–435, 2006.

[4] J. G. Ghaleh-Kandi, M. R. Valilu, Y. Ebrahimnazhad, R. S. Nobar, H. Karamouz, and M. Nazeri, “Effect of Different Levels of Perlite on Performance of broiler Chicks,” Adv. Environ. Biol., vol. 5, no. 4, pp. 776–779, 2011.

[5] J. G. Ghale-Kandi, R. Beheshti, H. Karamouz, Y. Ebrahimnazhad, K. Hatefinazhad, and N. Maheri-Sis, “Effect of Different Levels of Perlite on Sucrase Mucosal Enzymes Activity in Small Intestine of Broiler Clucks,” Glob. Vet., vol. 4, no. 2, pp. 103–107, 2010.

[6] A. Tatar, F. Boldaji, B. Dastar, S. Hassani, and S. Yalçin, “Effects of Dietary Supplementation with Perlite and Zeolite on Performance, Litter Quality and Carcass Characteristics of Broilers from 7- 42 Days of Age,” Int. Res. J. Appl. Basic Res., vol. 3, no. 6, pp. 1148–1154, 2012.

[7] F. K. Oguz, H. Gumus, M. N. Oguz, K. E. Bugdayci, H. Dagli, and Y. Ozturk, “Effects of different levels of expanded perlite on the performance and egg quality traits of laying hens,” Rev. Bras. Zootec., vol. 46, no. 1, pp. 20–24, 2017.

[8] A. Khodanazar, F. Boldaji, A. Tatar, and B. Dastar, “Effects of Dietary Zeolite and Perlite Supplementations on Growth and Nutrient Utilization Performance, and Some Serum Variables in Common Carp, (Cyprinus carpio),” Turkish J. Fish. Aquat. Sci., vol. 13, no. January, pp. 881–896, 2013.

[9] T. Bacic, “Recovery of valuable products from lees and integrated approach to minimise waste and add value to wine production,” 2003.

[10] S. Meunchang, S. Panichsakpatana, and R. W. Weaver, “Co-composting of filter cake and bagasse; by-products from a sugar mill,” Bioresour. Technol., vol. 96, no. 4, pp. 437–442, 2005.

[11] N. Zingelwa-Masekwana, “Management of fining and filter waste in wineries,” WineLand, no. September, pp. 115–117, 2012.

[12] E. T. Nerantzis and P. Tataridis, “Integrated Enology- Utilization of winery by-products into high added value products,” e-Journal Sci. Technol., vol. 1, no. 3, pp. 79–89, 2006.

[13] D. Yalcin, O. Ozcalik, E. Altiok, and O. Bayraktar, “Characterization and recovery of tartaric acid from wastes of wine and grape juice industries,” J. Therm. Anal. Calorim., vol. 94, no. 3, pp. 767–771, 2008.

[14] “Opportunities for the re-use of winery industry solid wastes (consultancy report),” PPK Environment & Infrastructure Pty Ltd for the Environment Protection Authority, 2001.

To download a .pdf of the Perlite Filter Aid and the Circular Economy brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright© 2021 Perlite Institute All Rights Reserved