This guide illustrates the use of expanded perlite to produce Perlite Concrete Blocks (PCBs).

The physical characteristics of expanded perlite are ideal for use as a constituent of lightweight insulating concrete for making Perlite Concrete Blocks (PCBs).

Perlite Concrete Blocks

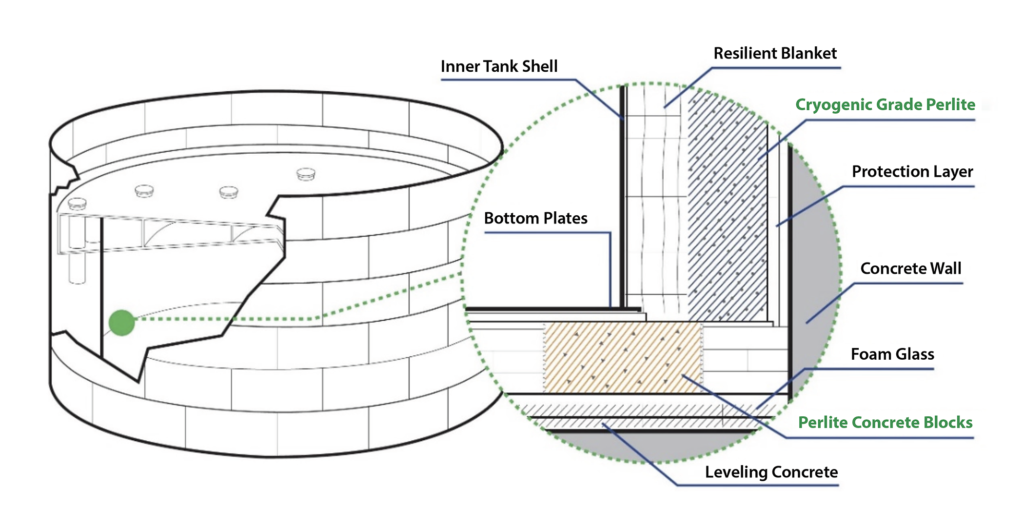

Perlite Concrete Blocks (PCBs) are engineered, lightweight, thermal insulating, reinforced, and waterproofed concrete blocks useful for, among other things, forming a bottom ring beam at the double-wall of cryogenic storage tanks. They provide excellent thermal insulation at negative temperatures and structural support against static and dynamic loads. PCBs are manufactured from a mix of Construction Grade expanded perlite aggregate, Portland cement, and admixtures. They are reinforced with steel or stainless-steel bars and lifting hooks and are manufactured under stringent quality standards to achieve consistent technical properties of compressive strength, thermal conductivity, density, and dimensional tolerances.

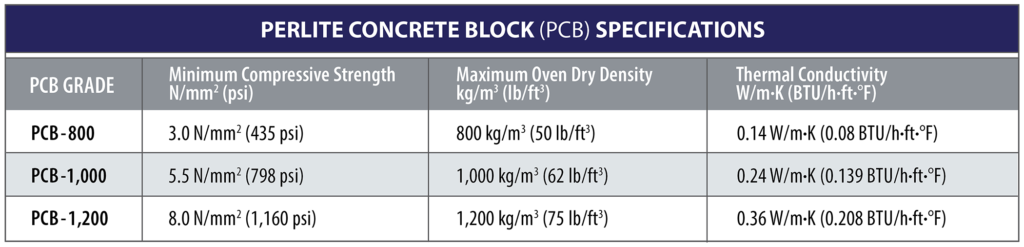

PCBs are custom-made according to a quality assurance plan and designed to deliver specific technical properties (see examples in Table 1).

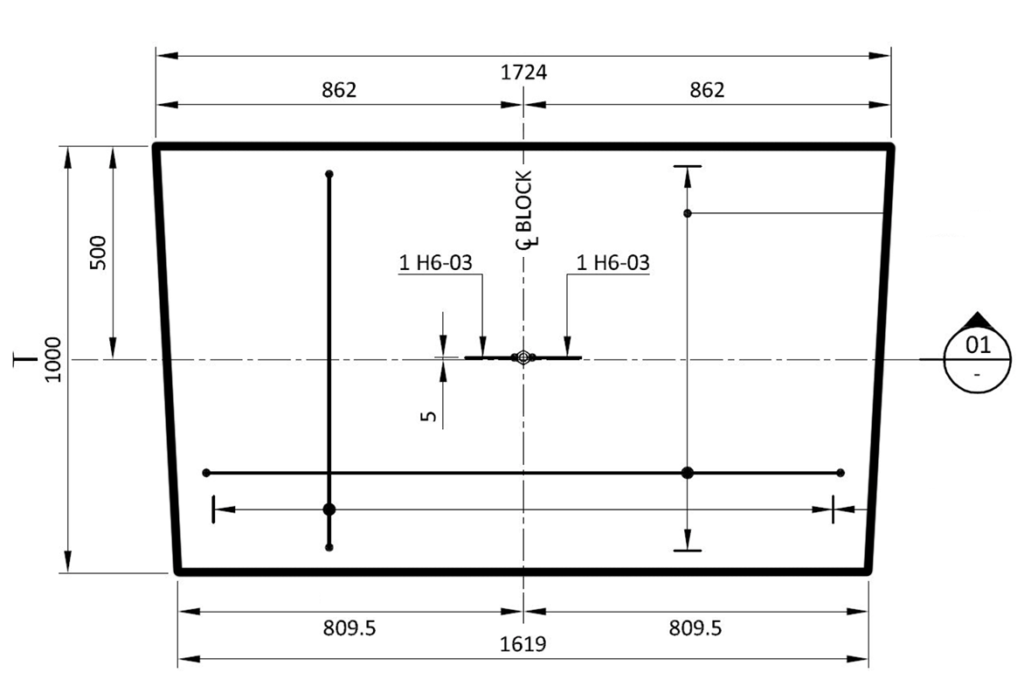

PCBs are cast in a trapezium shape, i.e., short/long lengths (Figure 2, below). This ensures a snug fit around the curvature of the tank and minimizes joints. (A typical arrangement is seen represented in Figure 4.)

Figure 2 • Example of an engineering detail of a Perlite Concrete Block (overhead perspective)

TECHNICAL ADVANTAGES OF PCBs

- Superior thermal insulation at negative temperatures

- High compressive strength

- Minimal water absorption

- Steel reinforcement for improved tensile strength

- Lifting hooks for easy handling

- Special vapor barrier coating to prevent moisture ingress during storage

- Completely non-combustible

REINFORCEMENT

The reinforcement specifications for Perlite Concrete Blocks vary depending on the loads involved and dimensions of the blocks needed. The specifications constitute an integral and critical part of the production process. Reinforcement acts to improve the tensile and flexural strength of the PCBs and minimize breakages. The type of reinforcement specified varies depending on the operating temperature of the Cryogenic double-walled tank and forces involved. For example, for an LNG tank operating at a temperature of -165°C (-265°F), stainless steel reinforcement is used. For a propane LPG tank operating at a temperature at -42°C (-44°F), normal carbon steel reinforcement is used.

APPLICATIONS

Perlite Concrete Blocks are applied to all types of double-walled tanks including:

- LNG Tanks

- Butane LPG and Propane LPG

- Ethane/Ethylene Tanks

To download a .pdf of the Perlite Concrete Blocks brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright© 2021 Perlite Institute All Rights Reserved