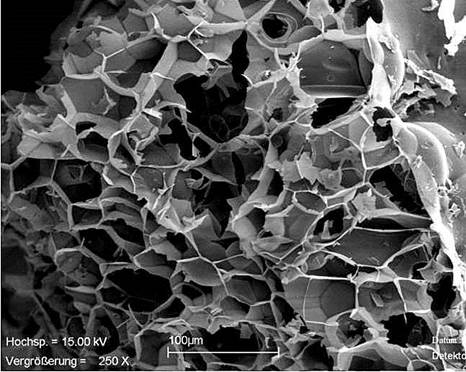

When perlite ore is expanded by exposure to controlled heating, it grows up to 20 times its original volume and takes on a foam-like cellular internal structure – essentially clusters of microscopic glass bubbles. Fine grades of perlite are mostly broken portions of these clusters, exhibiting a very large surface area, lending themselves to the efficient absorption of liquids. For a detailed explanation of perlite expansion, see PDF information sheet: “Why Perlite Works.”

Tests with various grades of expanded perlite fines have shown that perlite can absorb up to 8 times its dry weight of water.

Why Absorb Sludges?

Generally, waste landfills will not accept liquid wastes – they must be solidified or stabilized first. The measure of this solidification in the U.S. is established by the Environmental Protection Agency and is determined by a simple procedure called the “Paint Filter Test”. Basically, if no liquid drips out of a paint filter over a 5 minute test period, the material is defined as a solid.

Why Use Perlite?

Expanded perlite fines are especially useful in solidifying sludges because they can absorb a high percentage of liquid while adding minimal additional weight.

Absorption of liquids on solids is a simple process based on complex factors such as void volume, surface tension, surface area and liquid viscosity.

Of course, water, with its high surface tension and low viscosity, may show higher absorption than many other liquids. Testing is recommended to determine how much perlite is needed to stabilize specific types

of liquid waste or sludge.

To download a .pdf of the Perlite as a Sludge Absorbent brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright © 2016 Perlite Institute All Rights Reserved