The excellent insulating properties and loose-flow nature of perlite find wide application in the extreme-heat conditions of steel mills and foundries.

What is Perlite?

Perlite is not a trade name, but a generic term for naturally occurring siliceous volcanic rock. The distinguishing feature which sets perlite apart from other volcanic glasses is that when heated to a suitable point in its softening range, it expands from four to 20 times its original volume. This expansion is due to the presence of two to six percent combined water in the crude perlite rock.

When quickly heated to above 1600°F (870°C) the crude rock pops in a manner similar to popcorn as the combined water vaporizes and creates countless tiny bubbles in the heat softened glassy particles. It is these tiny glass-sealed bubbles, which account for the excellent insulating properties and lightweight of expanded perlite.

Expanded perlite can be manufactured to weigh from 2 lb/ft3 (32 kg/m3) to 11 lb/ft3 (180 kg/m3) making it especially suitable for use in insulating applications. Perlite is used in the manufacture of high temperature and cryogenic insulation, lightweight perlite insulating concrete, insulating board, insulating plasters, masonry wall insulation and as underfloor insulation.

High Temperature Applications

Perlite insulation is used in high temperature applications in the steel and foundry industries such as ladletopping, hot topping and risering, in topping compounds, in exothermic and insulating shapes, as a cushioning agent, in molding sand and in the manufacture of refractory blocks and bricks.

Ladle Topping and Filling

In ladle topping applications, expanded or unexpanded granular ore forms of perlite are added to molten metal pouring ladles. Most often the ore form is used which reacts with slag to allow easy removal of the slag layer. In cases where it is desirable to maintain a metal temperature in a ladle, the expanded perlite layer forms an efficient insulating blanket.

When perlite is introduced during ladle filling, a gentle rolling motion is produced which cleanses the metal by coagulating impurities. In addition, ladle lining life is increased by virtue of a vitreous residual coating left on the refractory by the perlite. An added advantage of perlite in this application is that no objectionable smoke or noxious fumes are produced.

Service to 1100 °C

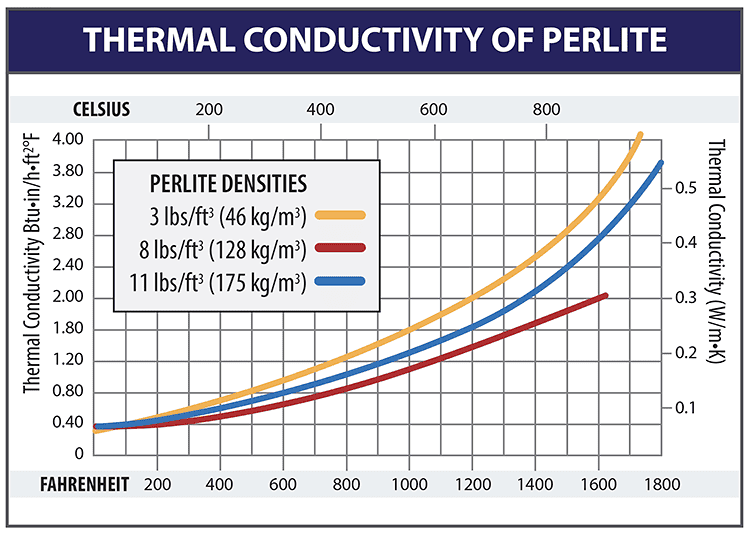

High temperature performance of expanded perlite insulation has been well documented over a period of many years. The data in Figure 1 details the thermal conductivity for various density perlite insulations up to 980°C. Although thermal conductivity increases appreciably above 980°C, expanded perlite has been used at service temperatures as high as 1100°C.

Hot Topping and Risering

Perlite is often mixed with exothermic powders and used in hot tops and risers to prevent shrinkage cavities in ingots and castings. Perlite is the most commonly used lightweight tiller used for these applications because of its availability, cost and superior properties. Normal additions of perlite to insulating and exothermic compounds are in the range of 3 to 20% by weight.

Formed shapes are often employed which take the form of hollow cylindrical sleeves for risers and panels for hot tops. These shapes perform essentially the same function as hot topping and risering powders and compounds.

Refractories

Perlite is used in the manufacture of refractories where the average temperature does not exceed approximately 2000°F (1100°C). Because of its excellent insulating properties, there is substantial usage of perlite in refractory castables, bricks, and blocks. In higher temperature applications, perlite refractories are often used as backup insulating layers for higher duty refractories.

Foundry Core and Molding Sand

Perlite is added to foundry core and molding sand mixtures as a cushioning agent to compensate for the expansion of crystalline silica as it goes through phase changes at temperatures in excess of 1000°F (540°C). Casting defects such as buckles, veining, fissuring and penetration are minimized and cleaning room costs are reduced. In addition, perlite improves permeability of core sands thus reducing defects attributable to poor venting.

CASE STUDY

After molten zinc pouring in kettle, expanded perlite is added creating a foamy layer at the top surface. The purpose of the layer is dual:

- To minimize heat losses from the ladle

- To produce a Thermal Protection layer

- To eliminate the contact of molten metal with oxygen/air and prevent oxidation

To download a .pdf of the High Temperature Applications for Perlite in the Steel and Foundry Industries brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright © 2023 Perlite Institute All Rights Reserved