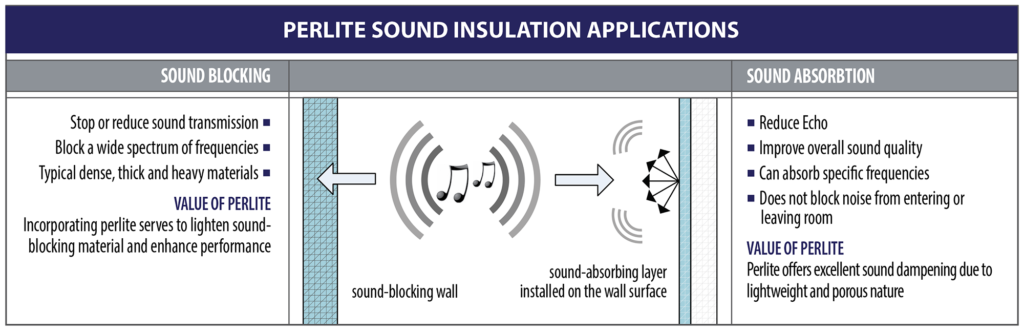

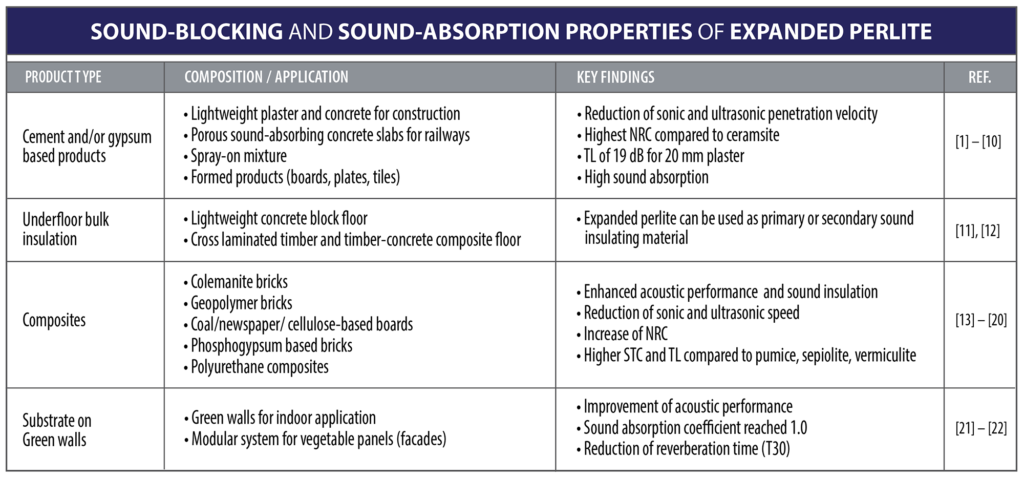

Discover the many sound-blocking and sound-absorbing uses for expanded perlite.

When it comes to noise protection in buildings, both sound-absorbing and sound-blocking (or soundproofing) materials come to mind. Each offers unique properties that make them suitable for specific applications.

Processes that Govern the Absorption of Sound by Acoustic Materials

First, in porous materials, sound energy is transformed into heat by the viscous forces at work when sound propagates through materials. Second, sound is dissipated by frictional forces when acoustic materials are set into vibration by the incident sounds.

How Perlite Works as a Sound Absorption/Blocking Material

The characteristic cellular structure of perlite and the successive air compartments hinder the propagation of sound waves, rendering it an ideal filler for sound-blocking and sound-absorbing applications. When used as a filler, sound waves can be consumed and absorbed by multiple levels due to the combination of an interconnected pore structure and cavity resonance sound absorption structure, resulting in a higher performance, sound absorption/blocking material.

Types of Noise

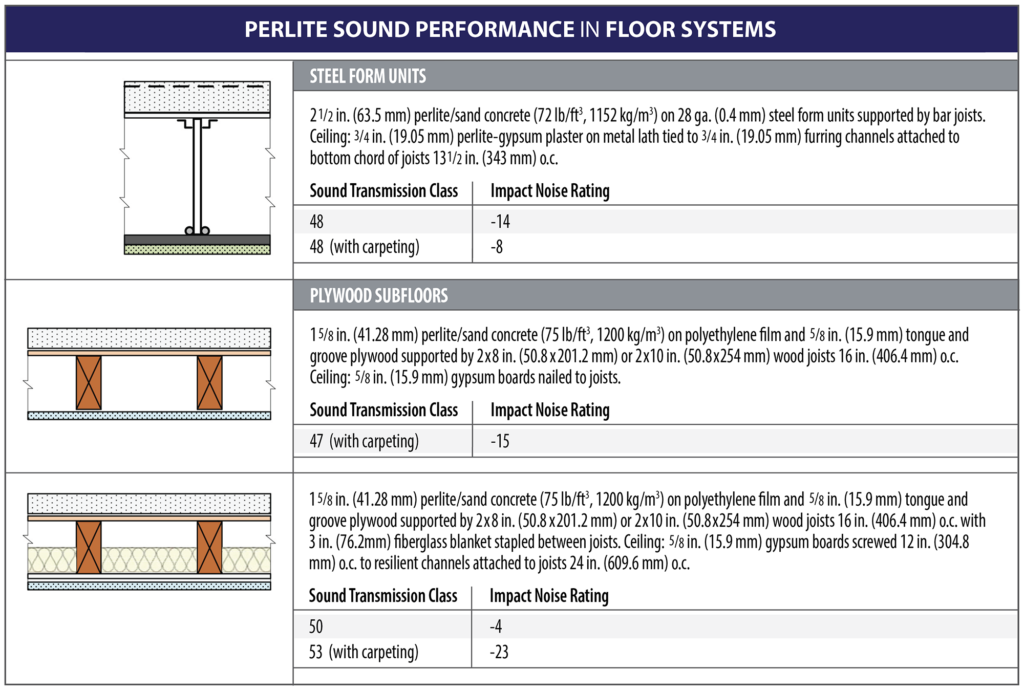

Airborne Noise – When airborne noise strikes a floor or ceiling, the surface is set to vibration by the fluctuating pressure of the sound waves. This vibration is what radiates sound into the air on the other side.

Impact Noise – Impact noise is caused by an object striking or sliding on a floor, such as footsteps, moving furniture or a door slamming. It can also be caused by an appliance, such as a dishwasher or shower, which transmits its vibration to the building structure.

Measurement Techniques and Units

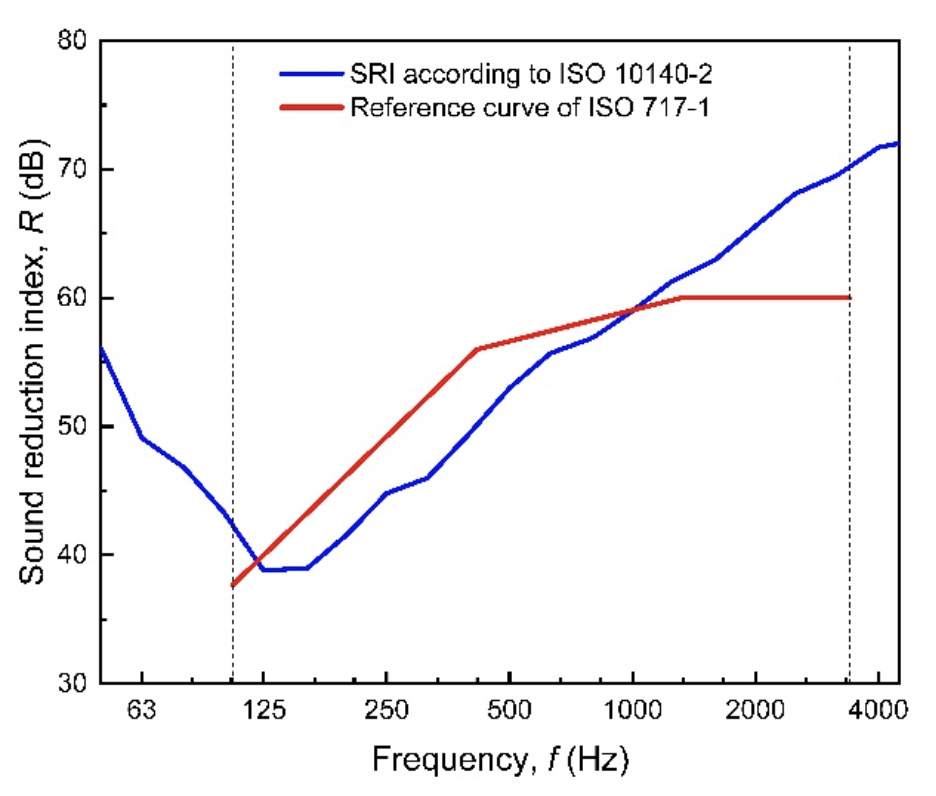

Reductions in unwanted sound transfer are typically expressed in terms of the Sound Transmission Class (or STC) in the U.S., or the Sound Reduction Index (SRI) outside the U.S. This is an integer rating how well a building partition reduces airborne sound. The STC rating roughly reflects the decibel reduction in noise that a partition provides.

In comparing sound absorbing materials for noise control purposes, the Noise Reduction Coefficient (NRC) is commonly used. NRC is the average usually stated to the nearest multiple of 0.05, of the coefficient at four frequencies 250, 500, 1000 and 2000 Hz.

Applications

Sound-Absorbing Perlite-Based Products – Expanded perlite is traditionally used as a primary constituent in the production of lightweight sound insulating panels and ceiling tiles. The intrinsic porous nature of lightweight expanded perlite absorbs sound waves and reduces the reverberation time.

Another option is the use of perlite as filler in spray-on absorbers. During spraying, perlite is mixed with a binding agent and water to produce a soft lightweight material with a coarse surface texture and high sound absorption characteristics[1]. In one application, spray-on absorber containing perlite achieved a NRC value of 0.70[2].

Sound-Blocking Perlite Products – Expanded perlite is an essential constituent of perlite lightweight concrete. Densities greater than 1,000 kg/m³ (62lb/ft³) offer a higher degree of sound-blocking. By varying the amount of perlite used in the mixture, one can achieve a balance between the weight of the overall structure, and the need for sound blocking performance. For a detailed explanation of perlite lightweight concrete, see Perlite Institute info sheet: Transit Mix Perlite Lightweight Concrete.

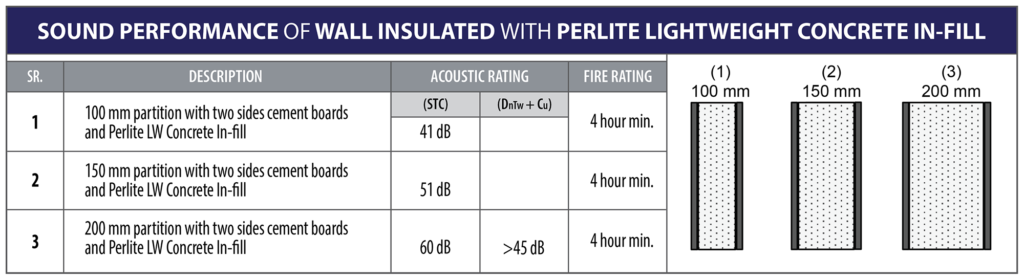

Most building codes now require floors, external walls, and intertenancy walls to comply with varying levels of sound insulation. For example, the airborne sound insulation per Approved Document E–UK for new dwellings is 45 DnTw + Ctr dB. By definition, this is the weighted Sound Reduction Index with the addition of a low frequency sound correction factor (Ctr).

Perlite manufacturers have developed a variety of solutions for harnessing the benefits of perlite lightweight concrete to meet the stringent local building code requirements. For example:

Perlite Lightweight Concrete Floor Sound-Blocking Solutions – Perlite lightweight concrete floor screed is used to reduce unwanted sound transfer between floors in a multilevel building. A typical perlite lightweight concrete floor installation with an oven dry density of 1,300 kg/m³, at a thickness of 50 mm (2 in.) applied directly (bonded) on 200 mm (8 in.) thick reinforced cement concrete (RCC) slab achieves an airborne sound rating of: Rw (C; Ctr) = 56,1 (-2 ; -6) dB. (Figure 2 and Figure 5).

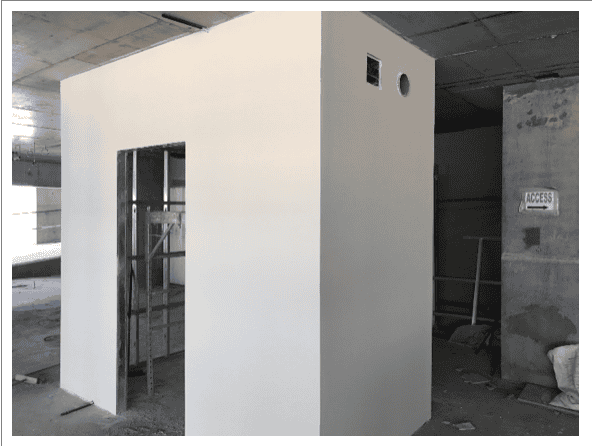

Perlite Lightweight Concrete In-Fill Partition Wall Systems – A sustainable drywall partition developed using perlite lightweight concrete in-fill at a density of 1,000 kg/m³ gives this partition wall system a minimum 4-hour fire rating and complies to 45 DnTw + Ctr dB for intertenancy walls (Figure 3). This is achieved with a thickness of 200mm (8 in.). Table 1 illustrates the sound performance index of the perlite-based partition system with varying thicknesses.

Further Benefits of Perlite When Used as a Filler in Construction Applications:

- Excellent thermal insulation

- Lightweight

- Safe to handle; non-toxic, inert and inorganic material

- Fireproof and non-combustible

- Resistance from corrosion from most chemicals

- Cost effective

- Low environmental impact

BIBLIOGRAPHY

[1] D. A. Harris, Noise Control Manual. Springer US, 1991.[2] Seddeq, H. Sound absorption improvement for cementitious materials. Can. Acoust. Acoust. Can. 38, (2010).

[3] Rashad, A. M. A synopsis about perlite as building material – A best practice guide for Civil Engineer. Constr. Build. Mater. 121, 338–353 (2016).

[4] Singh, M. & Garg, M. Perlite-based building materials – a review of current applications. Constr. Build. Mater. 5, 75–81 (1991).

[5] Birlik, G. Technical note: The contribution of perlite to the sound transmission loss of solid masonry walls. Build. Acoust. 8, 237–244 (2001).

[6] Garoum, M. et al. Investigation of sound absorption characteristics of loose and agglomerated perlite granulate. ICSV 2016 – 23rd Int. Congr. Sound Vib. From Anc. to Mod. Acoust. (2016).

[7] Zhao, C. et al. Reducing railway noise with porous sound-absorbing concrete slabs. Adv. Mater. Sci. Eng. 2014, (2014).

[8] Yilmazer, S. & Ozdeniz, M. B. The effect of moisture content on sound absorption of expanded perlite plates. Build. Environ. 40, 311–318 (2005).

[9] Yanjun, X. et al. The characteristics of perlite sound absorption board formed by vibration molding. Open Mater. Sci. J. 9, 39–42 (2015).

[10] Binici, H. & Aksogan, O. Insulation material production from onion skin and peanut shell fibres, fly ash, pumice, perlite, barite, cement and gypsum. Mater. Today Commun. 10, 14–24 (2017).

[11] Alyousef, R. et al. Experimental Study of New Insulation Lightweight Concrete Block Floor Based on Perlite Aggregate, Natural Sand, and Sand from Marble Waste. Adv. Mater. Sci. Eng. 2019, (2019).

[12] Zhang, X. et al. Experimental study on the impact sound insulation of cross laminated timber and timber-concrete composite floors. Appl. Acoust. 161, 107173 (2020).

[13] Top, S. et al. Properties of y ash-based lightweight geopolymer concrete prepared using pumice and expanded perlite as aggregates. J. Mol. Struct. 1202, 127236 (2020).

[14] Young, C. A. & Luttrell, G. H. Separation Technologies for Minerals, Coal, and Earth Resources. Separation Technologies for Minerals, Coal, and Earth Resources (Society for Mining, Metallurgy, and Exploration, 2012).

[15] Celik, A. et al. New lightweight colemanite-added perlite brick and comparison of physicomechanical properties with other commercial lightweight materials. Constr. Build. Mater. 62, 59–66 (2014).

[16] Maderuelo-Sanz, R. et al. Influence of the Microstructure in the Acoustical Performance of Consolidated Lightweight Granular Materials. Acoust. Aust. 44, 149–157 (2016).

[17] Li, T. et al. Applying vermiculite and perlite fillers to sound-absorbing/thermal-insulating resilient PU foam composites. Fibers Polym. 16, 691–698 (2015).

[18] Çelik, A. G. Investigation on characteristic properties of potassium borate and sodium borate blended perlite bricks. J. Clean. Prod. 102, 88–95 (2015).

[19] Aksogan, O. et al. An environment friendly new insulation material involving waste newsprint papers reinforced by cane stalks. J. Build. Eng. 15, 33–40 (2018).

[20] Ma, B. et al. Utilization of hemihydrate phosphogypsum for the preparation of porous sound absorbing material. Constr. Build. Mater. 234, 117346 (2020).

[21] D’Alessandro, F. et al. Experimental evaluation and modelling of the sound absorption properties of plants for indoor acoustic applications. Build. Environ. 94, 913–923 (2015).

[22] Thomazelli, R. et al. Sustainable Materials for Sound Absorption and Insulation: Acoustic properties of green walls. Proc. 22nd Int. Congr. Acoust. (2016).

To download a .pdf of the Perlite in Sound Insulation Applications brochure, click here.

If you have technical questions on this topic, please email the technical contacts listed on our contact page.

Copyright © 2020 Perlite Institute All Rights Reserved